31

0750-M001-0

4.4

Montaggio della piattaforma

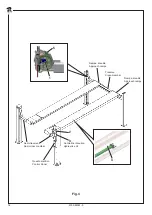

Con riferimento alla figura

10

:

A) Posizionare e fissare al pavimento le colonne anteriori (

1

) tramite gli appositi tasselli, dopo avere eseguito le forature Ø 5/8”

x profondità 4” (diametro 16 mm - profondità 100 mm) come illustrato in

Fig. 10

. Occorre rispettare in particolar modo le quote

E2

(toll/- 3/64” (+/- 1 mm)),

F

,

F2

,

G2

. Al termine di questa operazione è importante verificare la perpendicolarità di

ciascuna colonna (

1

) rispetto al pavimento, spessorando dove neccessario le piastre di base (toll/- 3/64” (+/- 1 mm)).

B) Su entrambe le colonne (

1

) rimuovere:

- il carter di copertura,

- l’asta asolata (

2

), la protezione salvadita (

3

), il blocchetto (

4

) e le piastre superiori (

5

) e (

6

).

C) Inserire le semitraverse (

7A

e

7B

) dall’alto delle colonne (1).

Prestare attenzione:

la traversa (

7B

), dotata dei fori per il fissaggio della camma finecorsa, deve essere installata sulla colonna

comandi.

D) Fare scorrere verticalmente ciascuna semitraversa (

7

) lungo la colonna ed identificare il punto di minima distanza tra i pattini

(

8

) ed i tubolari (

9

).

Inserire appositi spessori (

10

) dietro ai pattini (

8

) per ridurre al minimo il gioco rispetto ai tubolari (

9

).

4.4

Platform installation

Refer to figure

10

:

A) After having carried out the necessary holes Ø 5/8” x depth 4” (diameter 16 mm - depth 100 mm) as shown in

Fig. 10

, set and

secure to floor front posts (

1

) by means of the suitable anchors. The following values shall be complied with:

E2

(tol/

- 3/64” (+/- 1 mm)),

F

,

F2

,

G2

. Once this operation is completed, it is necessary to check that each post (

1

) is at right angles to

the floor, shimming, where needed, the base plates (tol/- 3/64” (+/- 1 mm)).

B) Remove on both posts (

1

):

- cover,

- slotted bar (

2

), finger guard (

3

), block (

4

) and upper plates (

5

) and (

6

).

C) Fit semi-cross members (

7A

and

7B

) from posts (

1

) upper side.

Warning:

the cross member (

7B

), provided with the suitable holes for the limit switch cam fastening, shall be installed onto the

control post.

D) Vertically slide each semi-cross member (

7

) along the post and identify the minimum distance point between sliding shoes (

8

)

and tubular structures (

9

).

Fit suitable shims (

10

) behind sliding shoes (

8

) in order to reduce to a minimum the clearance with respect to tubular structures

(

9

).

Summary of Contents for 0750-M001-0

Page 9: ...SAFETY WARNING LABELS for Four Post Surface Mounted Roll on Lifts...

Page 10: ......

Page 11: ......

Page 14: ...0750 M001 0 14 Fig 2 1 1 G 14000 lbs...

Page 24: ...0750 M001 0 24 Fig 7...

Page 34: ...0750 M001 0 34 18 14 18 15 16 18 18 7 G Fig 12...

Page 36: ...0750 M001 0 36 Fig 13 5 4 6 8 9 7 1 3 2 10...

Page 38: ...0750 M001 0 38 Fig 14 7 8 6 3 4 5 1 3 2 10 11 9 3...

Page 40: ...0750 M001 0 40 Fig 15 1 5 2 4 3 3 1...

Page 42: ...0750 M001 0 42 Fig 16 EV3 2 A B C 1 3 4 6 D D EV3 E 7 7 9 8 5 10...

Page 48: ...0750 M001 0 48 Fig 19 1 2 3...

Page 52: ...0750 M001 0 52 1 3 2 4 Fig 21...

Page 54: ...0750 M001 0 54 Fig 22 3 1 5 5 5 4 4 5 2 6 Fig 23 1 2 3 2 1 3 2 2 Fig 24 4 5 6...

Page 60: ...0750 M001 0 60 2 Fig 25 1 3 4...

Page 62: ...0750 M001 0 62 Fig 27 Fig 26 3...

Page 99: ...99 99 0750 M001 0 NOTE NOTES...