6.0 System Details

9

6.1

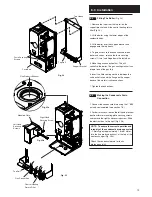

Water Circulating Systems

1. The appliance is suitable for fully pumped

sealed systems only.

The following conditions should be observed

on all systems:

• The boiler must not be used with a direct

cylinder.

• Drain cocks should be fitted to all system low

points.

• All gas and water pipes and electrical wiring

must be installed in a way which would not

restrict the servicing of the boiler.

• Air vents should be fitted to all system high

points.

• Best practice recommends that an appropriate

size air separator is fitted, to expel the air from

the system. This will reduce corrosion potential

and maximise the efficiency within the system.

6.2

Treatment of Water Circulating

Systems

• All recirculatory water systems will be subject to

corrosion unless an appropriate water treatment

is applied. This means that the efficiency of

the system will deteriorate as corrosion sludge

accumulates within the system, risking damage

to pump and valves, boiler noise and circulation

problems.

• When upgrading existing systems that exhibit

evidence of sludging, it is advisable to clean the

system prior to treatment in order to remove any

sludge and reduce the likelihood of these

deposits damaging new components.

• When fitting new systems flux will be evident

within the system, which can lead to damage of

system components.

• All systems must be thoroughly drained and

flushed out. The recommended flushing and

cleansing agents are Betz-Dearborn Sentinel

X300 or X400 and Fernox Superfloc Universal

Cleanser which should be used following the

flushing agent manufacturer’s instructions.

• System additives - corrosion inhibitors and

flushing agents/descalers should be suitable for

aluminium and comply to BS7593 requirements.

The only system additives recommended are

Betz-Dearborn Sentinel X100 and Fernox-Copal

which should be used following the inhibitor

manufacturer’s instructions.

Failure to flush and add inhibitor to the

system will invalidate the appliance warranty.

• It is important to check the inhibitor

concentration after installation, system

modification and at every service in accordance

with the manufacturer’s instructions. (Test kits are

available from inhibitor stockists.)

• For information or advice regarding any of the

above contact the Potterton Helpline.

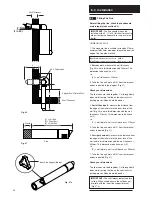

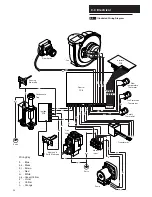

Boiler

Hot water

Central

heating

load

Live feed

to pump

Switch live from

programmer, etc.

S/L

N P/F

Fig. A

Wiring an extra pump to the pump feed

connection of boiler

Boiler

Connections