7.0 Site Requirements

12

7.1

Information

WARNING

- Check the information on the data

plate is compatible with local supply conditions.

1. The installation must be carried out by a CORGI

Registered Installer or other registered competent

person and be in accordance with the relevant

requirements of the current

G

AS

S

AFETY

(Installation

and Use)

R

EGULATIONS

, the

B

UILDING

R

EGULATIONS

(Scotland)(Consolidation), the

L

OCAL

B

UILDING

R

EGULATIONS

, the current

I.E.E. W

IRING

R

EGULATIONS

and the bye laws of the

L

OCAL

W

ATER

U

NDERTAKING

.

Where no specific instruction is given reference should

be made to the relevant

BRITISH STANDARD

CODES OF PRACTICE

. For Ireland install in

accordance with IS 813 “I

NSTALLATION OF

G

AS

A

PPLIANCES

”. Reference should also be made to

B

RITISH

G

AS

G

UIDANCE

N

OTES

F

OR

T

HE

I

NSTALLATION OF

D

OMESTIC

G

AS

C

ONDENSING

B

OILERS

.

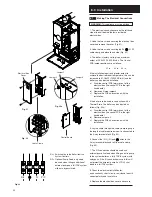

7.2

B.S. Codes of Practice

Standard

Scope

BS 6891

Gas Installation.

BS 5546

Installation of hot water supplies for

domestic purposes.

BS 5449 Part 1

Forced circulation hot water systems.

BS 6798

Installation of gas fired hot water boilers.

BS 5440 Part 1

Flues.

BS 5440 Part 2

Ventilation.

BS 7074

Expansion vessels and ancillary

equipment for sealed water systems.

BS 7593

Treatment of water in domestic hot water

central heating systems.

WARNING

- The addition of anything that may

interfere with the normal operation of the appliance

without the express written permission of Potterton

could invalidate the appliance warranty and infringe

the

G

AS

S

AFETY

(Installation and Use)

R

EGULATIONS

.

7.3

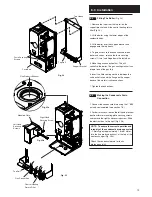

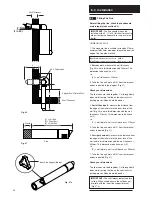

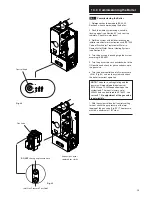

Clearances

(Figs. 12 &13)

1. A flat vertical area is required for the installation

of the boiler.

2. These dimensions include the necessary

clearances around the boiler for case removal,

spanner access and air movement. Additional

clearances may be required for the passage of

pipes around local obstructions such as joists

running parallel to the front face of the boiler.

3. For unventilated compartments see Section 7.5.

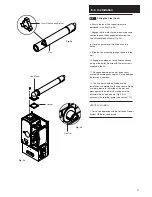

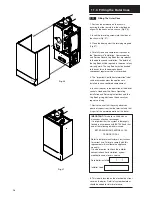

7.4

Location

NOTE:

Due to the nature of the boiler a plume of

water vapour will be discharged from the flue. This

should be taken into account when siting the flue

terminal.

1. The boiler may be fitted to any suitable wall with

the flue passing through an outside wall or roof and

discharging to atmosphere in a position permitting

satisfactory removal of combustion products and

providing an adequate air supply. The boiler should

be fitted within the building unless otherwise

protected by a suitable enclosure i.e. garage or

outhouse. (The boiler may be fitted inside a

cupboard - see Section 7.5).

2. If the boiler is sited in an unheated enclosure

then it is recommended to incorporate in the system

controls a suitable device for frost protection.

3. If the boiler is fitted in a room containing a bath or

shower reference must be made to the current

I.E.E. W

IRING

R

EGULATIONS

and

B

UILDING

R

EGULATIONS

. If the boiler is to be fitted into a

building of timber frame construction then reference

must be made to the Institute of Gas Engineers

document UP 7.

200mm

850mm

490mm

200mm

5mm Min

5mm Min

5mm

500mm

For Servicing

Purposes

Fig. 12

Fig. 13

In Operation

3°

(1 in 20)

325mm