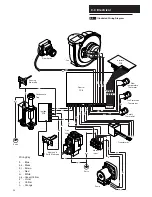

8.0 Installation

17

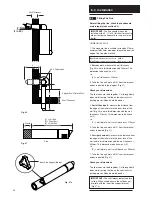

Wall Thickness

up to 227mm

up to 750mm

up to 1200mm

Flue Hole ø

125mm core drill

150mm core drill

175mm core drill

Check Site Requirements (section 7.0) before

commencing.

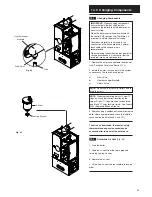

8.1

Initial Preparation

The gas supply, gas type and pressure must

be checked for suitability before connection

(see Section 7.6).

NOTE:

If the boiler is to be pre-plumbed,

follow both these instructions and those on

the boiler pack.

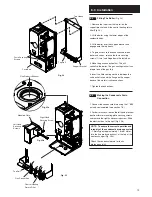

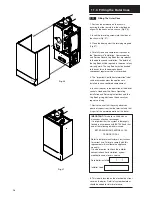

1. Remove the fixing template (Fig. 20) from the

fixing carton.

2. After considering the site requirements

(see Section 7.0) position the template on the

wall ensuring it is level both horizontally and

vertically.

3. Mark the position of the top centre hole for the

wallplate.

4. Mark the condensate discharge pipe area.

5. Mark the centre of the flue hole (rear exit). For

side exit, mark as shown. If required, mark the

position of the gas and water pipes. Remove the

template.

6. Cut the hole for the flue (minimum diameter

125mm) (see table opposite for wall thickness

flue diameter’s).

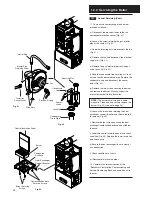

7. Drill and plug the wall as previously marked.

Secure the wallplate to the wall by the top centre

hole.

8. Ensuring the wallplate is level both

horizontally and vertically, drill and plug the

remaining 4 securing positions at the top and

bottom through the wallplate. Utilising the slots

available ensure the wallplate is square and

secure to the wall.

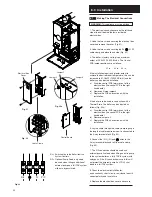

9. Connect the gas, water and the pressure relief

discharge pipes to the valves on the support

bracket using the copper tails supplied. Ensure

the sealing washers are fitted correctly to the

water connections.

10. Loosely route the condensate discharge pipe

to the area previously marked.

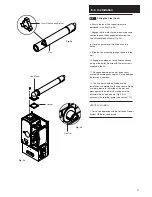

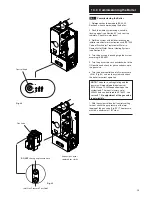

8.2

Flushing

1. Insert a tube into the valve outlet furthest from

the filling loop (Fig. 21).

2. Flush thoroughly (see System Details, Section

6.0).

Fig. 20

Plastic Flushing Tube

MINIMUM CLEARANCE 5mm EACH SIDE

37mm

ELECTRICAL SUPPLY

GENERAL AREA FOR

CENTRE LINE OF FLUE AT 3 DEGREES

CENTRE LINE OF FL

UE AT 3 DEGREES

TO 750mm (30")

WALL THICKNESS UPTO 227mm (9")

CENTRE FOR DIA.150mm (6") HOLE

WALL THICKNESS UPTO 227mm (9")

CENTRE FOR DIA. 125mm (5") HOLE

WALL THICKNESS UPTO 227mm (9")

CENTRE FOR DIA. 125mm (5") HOLE

NOTE : FOR EACH 1m OF HORIZONTAL FLUE ADD 55mm OF CLEARANCE ABOVE THIS LINE

APPLIANCE OUTLINE

PROMAX SYSTEM HE

BOILER

FIXING TEMPLATE PART No. 5106702p

FLOW

RETURN

DRAIN

CONDENSATE

SUPPLY

GAS

RELIEF

PRESSURE

BOILER CENTRE LINE

Fixing Template

Fig. 21