13.0 Changing Components

30

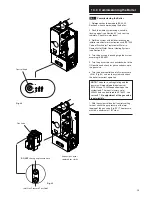

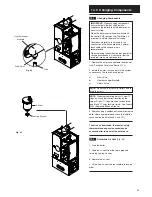

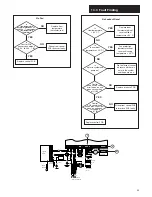

13.3

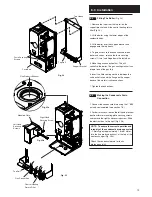

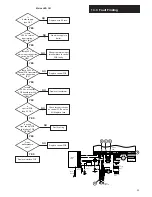

Flowswitch

(Fig. 46)

1. Drain the boiler

(see Section 13.1 paragraph 2 & 3).

2. It may be necessary to remove the expansion

vessel (see Section 13.5).

3. Remove the clip securing the flow pipe to the

flowswitch.

4. Remove the two screws securing the flow

switch to the boiler.

5. Disconnect the inline electrical connection.

6. Remove the flowswitch.

7. Fit the new flowswitch and reassemble in

reverse order.

8. Recommission the boiler and check the

inhibitor concentration (see Section 6.2 and 10.1).

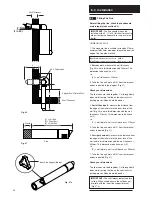

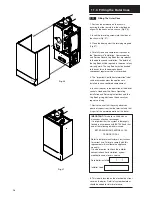

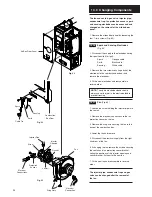

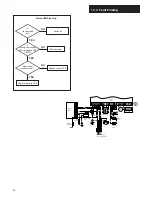

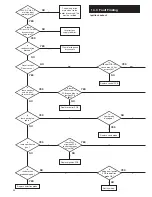

13.4

Flow Temperature Thermistor and

Safety Thermostat

(Fig. 47)

1. The procedure is the same for both the

thermistor and the safety thermostat.

2. Remove the electrical connections from the

sensor.

3. Unscrew the sensor from the pipe.

4. Fit the new thermistor or safety thermostat and

reassemble in reverse order.

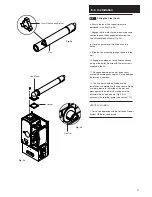

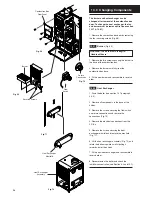

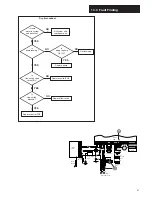

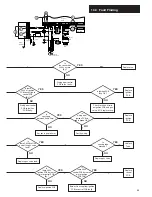

13.5

Expansion Vessel

(Fig. 48)

1. Drain the boiler

(see Section 13.1 paragraph 2 & 3).

2. Loosen the securing screw at the base of the

expansion vessel.

3. Whilst supporting the vessel undo the

expansion vessel connection and retain the

sealing washer.

4. Remove the expansion vessel.

5. Fit the new expansion vessel and reassemble

in reverse order.

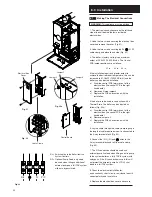

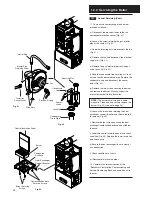

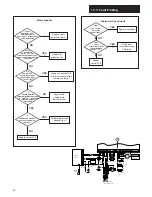

13.6

Re-pressuring Expansion vessel

1. The charge pressure is 1.0 bar.

2. Close the central heating flow and return

isolating valves.

3. Drain the boiler

(see Section 13.1 paragraph 2 & 3).

4. The “Schraeder” valve is positioned centrally at

the side of the appliance. Pressurise to 1.0 bar.

5. Open the isolating valves and recharge the

system to between 1.0 bar and 2.5 bar. Vent the

system as necessary.

Flowswitch

Clip

Flow Pipe

Fig. 46

Fig. 47

Fig. 48

Expansion Vessel

Connection

Expansion Vessel

Securing Screw

Expansion Vessel