F5 Series Valves - Valve Body Service

V-431BP

7. Remove a new spool assembly (19) from its protective bag and grease

seals and bore. Then insert spool into valve bore, taking care to

install squarely and push slowly to avoid damaging seals or the valve

bore.

8. Lightly grease new gasket (18) and place into its gasket track on

operator. Depending upon the type of valve being serviced, certain

seals in the service kit may not be used. See Figure 1 for the correct

gasket. Lightly press the gasket into its gasket track, pushing knob

projections into gasket holes.

9. Apply a light film of grease to piston bores and all surfaces of piston

seals. Install seals onto piston with the lips of the seals facing away

from the support flange. See Figure 3.

10. Install the piston (16) & lip seal (17) subassembly into its operator

bore, taking care to assure that the lips of the seal pass smoothly

into the bore.

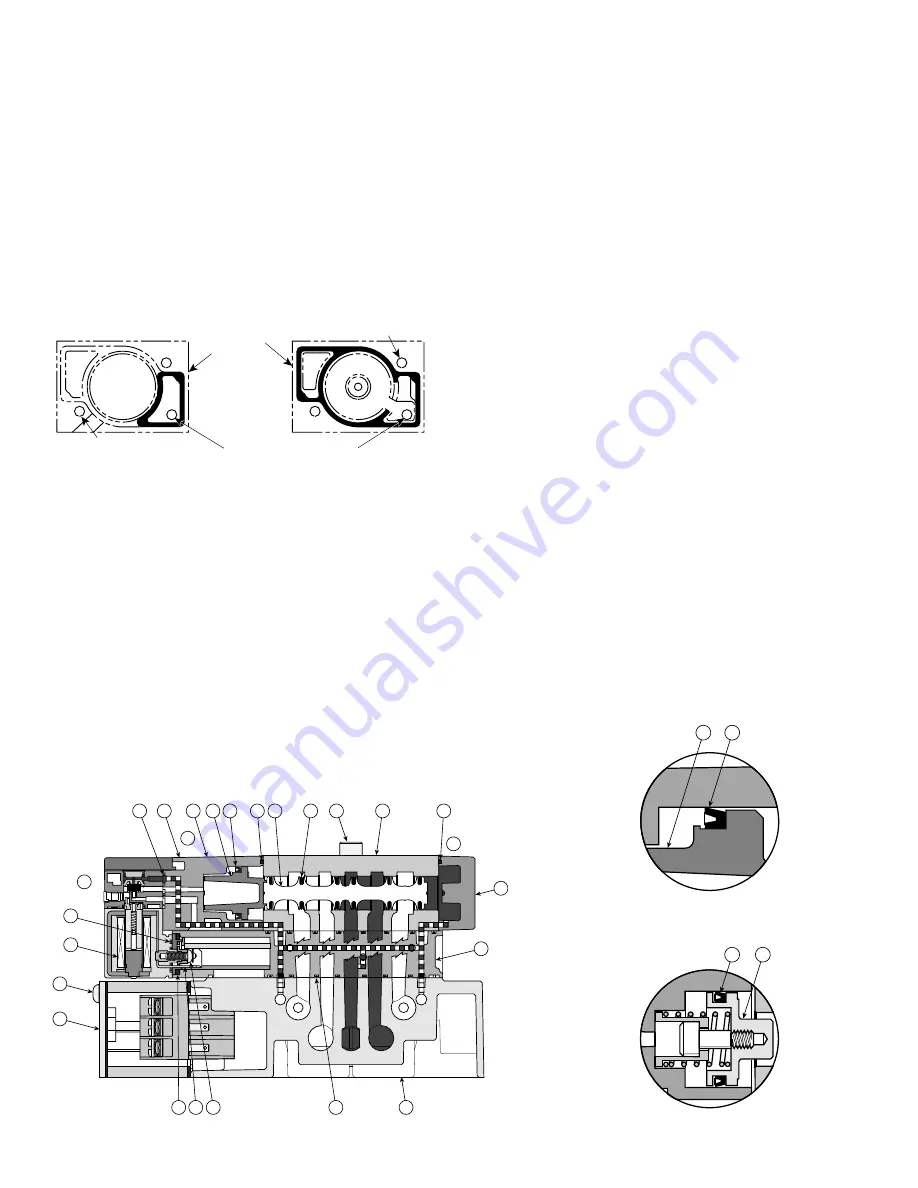

FIGURE 1: Gaskets for Operators

Pilot Adapter

Return End Cap

NOTE: This gasket is used on

NOTE: This gasket is used on

valves with piston vent and

valves with piston vent and pilot

pilot exhaust out the valve side.

exhaust internally exhausted.

11. Assemble the operator adapter (15) to the valve body (22) using its

two mounting screws (14). Tighten screws from 0.9 to 1.4 N•m

(8 to 12 in-lbs).

NOTE: Be sure to lightly grease the new rectangular gasket (6) and

then place it into the bottom of the rectangular cavity in the

sandwich block.

12. Assemble the solenoid subassembly (4, 9, 10, & 13) onto the

operator adapter (15) using its two mounting screws (11). Tighten

these screws from 0.9 to 1.4 N•m (8 to 12 in-lbs).

13. Assemble the end cap &/or air operator onto the valve body (22)

using two mounting screws (25). Be sure to position end cap so that

its gasket lines up with the air supply hole in the valve body. Tighten

these screws from 0.9 to 1.4 N•m (8 to 12 in-lbs).

14. Check to insure that the gasket (3) on the bottom of the sandwich

block is still properly seated in its gasket track. Then place valve

assembly on top of base (2). Line up electrical plug with socket in

base and gently press down on valve to seat plug properly.

Part Identification List

Item #

Description

1

Sandwich Block

2

Base (subbase or modular manifold)

3

Molded Gasket - sandwich block to base

4

Screw - solenoid coil to operator adapter

5

Electrical Pin

6

Rectangular Gasket - sandwich block to solenoid coil

7

Captive Mounting Screws - end cover to base

8

End Cover

9

Solenoid Coil

10

Gasket - solenoid coil to sandwich adapter

11

Mounting Screw - solenoid coil to operator adapter (not shown)

12

Gasket - operator to operator adapter

13

Sandwich Adapter

14

Screw - operator adapter to valve body (not shown)

15

Operator Adapter

16

Piston (2-Position) or Piston Assembly (3-Position) -

for operator adapter

17

Lip Seal - piston to operator adapter

18

Gasket - operator adapter to valve body

19

Spool Assembly

20

Seals - spool to valve body

21

Captive Mounting Screw - valve body to base

22

Valve Body

23

Screw - end cap to valve body (not shown)

24

Return End Cap

Instruction Sheets Available:

V-430CP - Valve Installation & Operating Instructions

V-432BP - Solenoid Service Instructions

V-433BP - Manifold Installation Instructions

V-434BP - Subbase Installation Instructions

V-435BP - Sandwich Flow Control Installation Instructions

V-436BP - Sandwich Regulator Installation & Operating Instructions

V-437BP - Sandwich Regulator Conversions & Service Instructions

V-438BP - Manifold With Electrical Interconnect Installation

FIGURE 2: Single Solenoid 2-Position Valve Shown

FIGURE 4: Piston Assembly

for 3-Position Valves

FIGURE 3: Enlarged View

of Piston & Lip Seal

16

17

16

17

14

12

COM

BP

1

BP

14

12

1

2

4

5

3

13

12

14

15 16 17

18

18

1

24

9

11

10

8

7

23

19

20

22

2

3

4

5

6

21

Location of Pilot Hole

Mounting Hole

Outline of

End Cap

Mounting Hole

15. Line up the mounting holes and tighten the captive mounting screws

(21). Torque screws at 2.8 to 3.9 N•m (25 to 35 in-lbs) using progressive

steps with a criss-cross pattern.

16. Apply inlet pressure and check for leaks. If any are present, do not

operate the valve - repeat this assembly process until satisfactory.