137

DP-8032/8025

2008

Ver. 1.2

4.5.

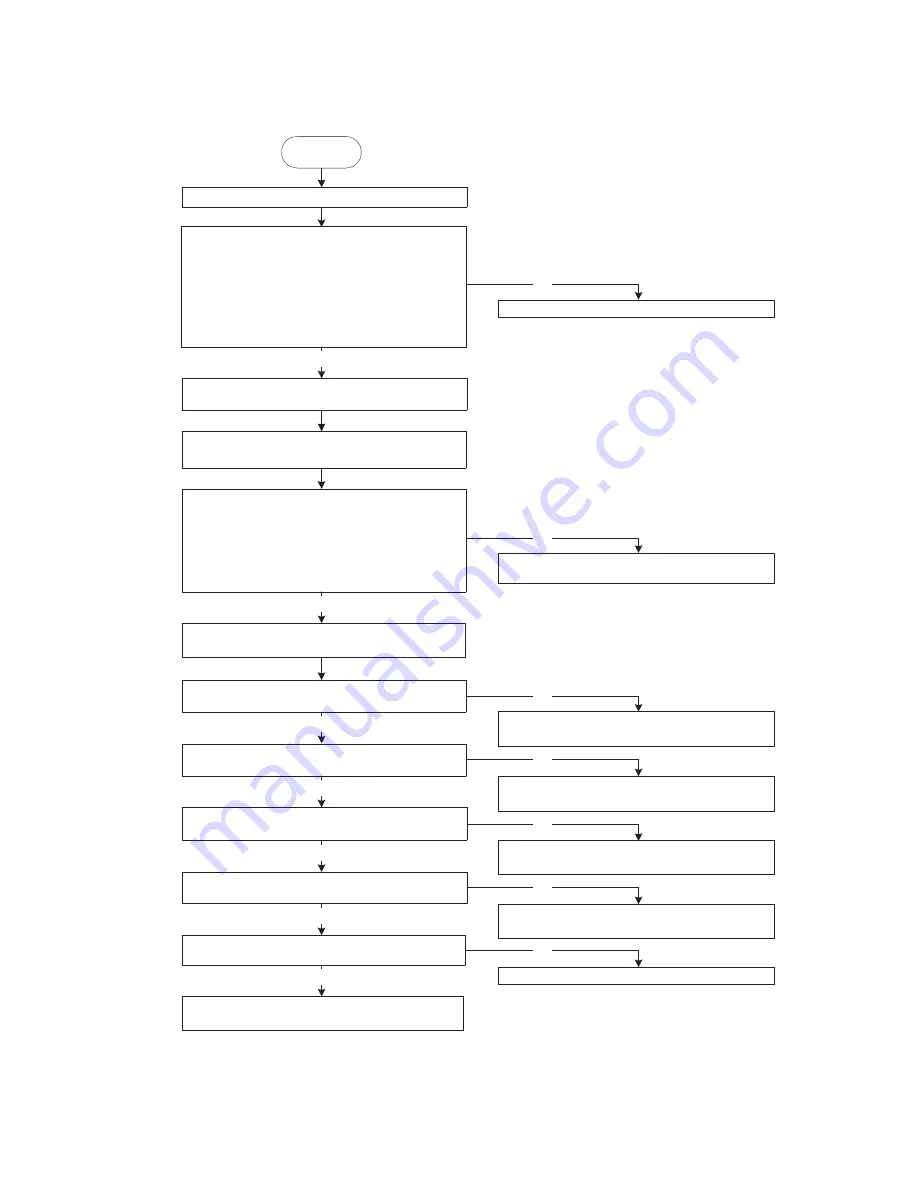

Troubleshooting the LAN Interface

4.5.1.

Checking Network Configuration

START

From the DOS Prompt, enter the following

command-line utility: ipconfig /all

Locate a PC connected to the same Subnet

Mask as the unit

Does the displayed Network configuration,

match the following settings of the unit

Internet Parameters ?

Print the current Internet Parameters List

Does the DNS Server respond to the

"ping IP" command ?

From the DOS Prompt, enter the following

command-line utility: "route print"

Does the current routing table for the

Gateway match ?

Ask the Network Administrator to correct

the routing table on that Gateway.

Ask the Network Administrator to

verify the proper information.

Check the power switch, cables , and the

current settings of unit.

Does the Default Gateway respond to the

"ping IP" command ?

Ask the Network Administrator to check the

Default Gateway, and system status.

Does the unit respond to the

"ping host name" command ?

Ask the Network Administrator to check the

Default Gateway, and system status.

Ask the Network Administrator to verify the

POP/SMTP account, and system status.

Does the unit respond to the

"telnet" command ?

Replace the SC PCB

Ask the customer for the Pre-Installation

Information form filled out by the Network

Administrator.

Verify this information with the Internet

Parameters List that you just printed.

Are the Internet Parameters entered

correctly into the unit?

Re-enter the Internet Parameters correctly.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

Default Gateway IP Address:

DNS Server IP Address:

Subnet Mask:

Summary of Contents for DP-8032

Page 2: ...2 ...

Page 3: ...3 ...

Page 5: ...5 Hinweis Beispiel ...

Page 9: ...9 ...

Page 10: ...10 ...

Page 11: ...11 ...

Page 12: ...12 memo ...

Page 397: ...Published in Japan ...