8-15

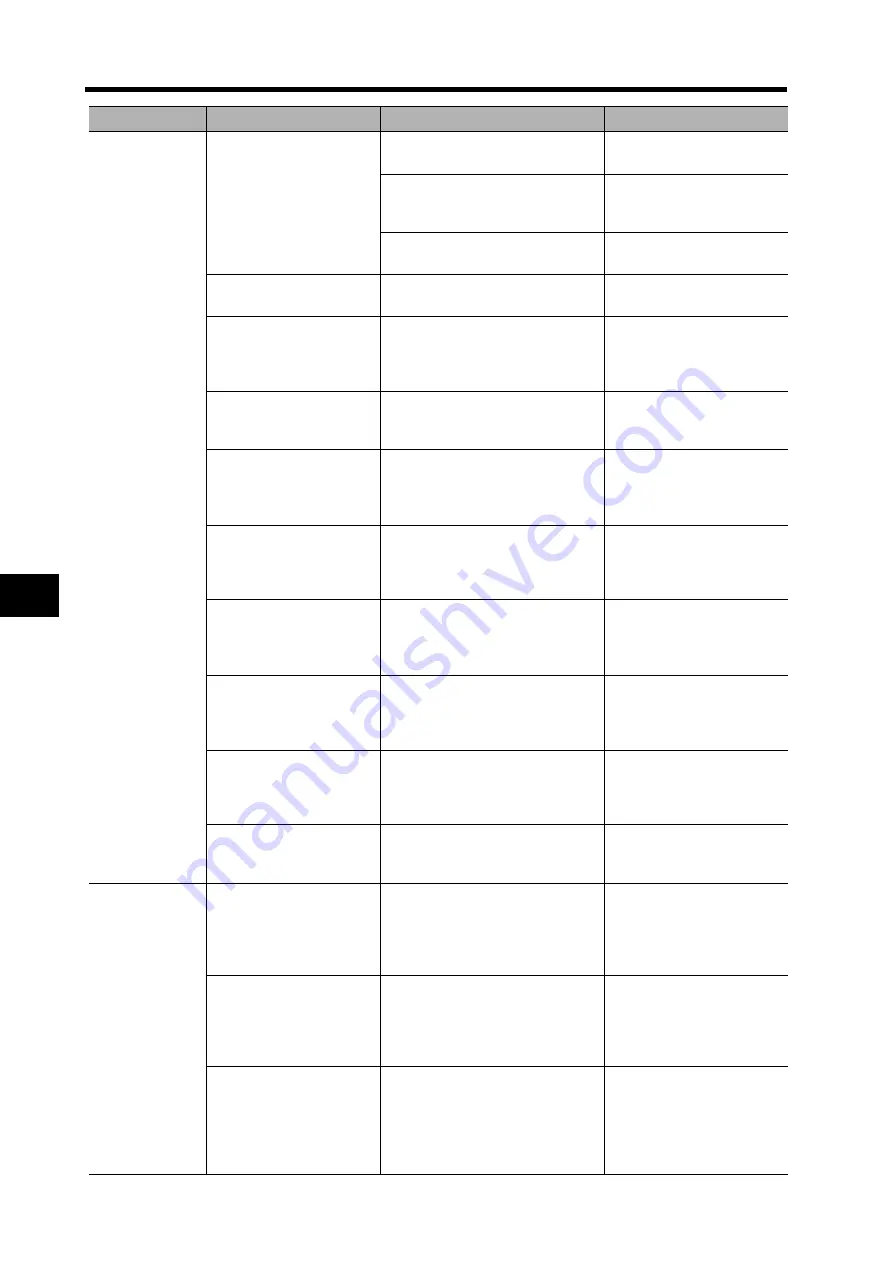

8-3 Troubleshooting

8

Troubleshooting

The Servomotor

is producing un-

usual noises or

the machine is

vibrating.

(Continued on

next page.)

There are problems with

the machine’s installation.

Check whether the Servomotor’s

mounting screws are loose.

Tighten the mounting

screws.

Check whether the axes are mis-

aligned in the mechanical coupling

system.

Align the mechanical cou-

plings.

Check whether the coupling is un-

balanced.

Adjust the coupling’s bal-

ance.

There is a problem with the

bearings.

Check for noise or vibration around

the bearings.

Contact your OMRON repre-

sentative.

The gain is doesn’t match.

According to load (non-load is in-

cluded), adjust an inertia ratio and

a gain to a suitable value from fac-

tory setting.

•

Use autotuning.

•

Perform manual tuning.

The Speed Feedback Fil-

ter Time Constant (Pn13)

is wrong.

Check the setting of Pn13.

Return the setting to 4 (de-

fault) or increase the setting.

Noise is entering the Con-

trol I/O Cable because the

cable does not meet spec-

ifications.

Check that the cable wire is a twist-

ed-pair wire or shielded twisted-

pair cable with wires of at least

0.08 mm

2

.

Use the Control I/O Cable

that meets specifications.

Noise is entering the Con-

trol I/O Cable because the

cable is longer than the

specified length.

Check the length of the Control I/O

Cable.

Shorten the Control I/O Ca-

ble to 3 m or less.

Noise is entering the cable

because the Encoder Ca-

ble does not meet specifi-

cations.

Check that the cable wires are

twisted-pair wires or shielded twist-

ed-pair wires that are at least

0.12 mm

2

.

Use the Encoder Cable that

meets specifications.

Noise is entering the En-

coder Cable because the

cable is longer than the

specified length.

Check the length of the Encoder

Cable.

Shorten the Encoder Cable

to 20 m or less.

Noise is entering the signal

wires because the Encod-

er Cable is stuck or the

sheath is damaged.

Check whether the Encoder Cable

is damaged.

Correct the Encoder Cable’s

pathway to prevent damage.

Too much noise is entering

the Encoder Cable.

Check whether the Encoder Cable

is tied up in a bundle with or too

close to high current lines.

Lay the Encoder Cable in a

way surges are not applied.

The Servomotor

is producing

unusual noises

or the machine is

vibrating.

(Continued from

previous page.)

The FG’s potential is fluc-

tuating due to devices near

the Servomotor, such as a

welding machine.

Check for grounding problems (fail-

ure to ground or incomplete

grounding) at devices such as a

welding machine near the Servo-

motor.

Ground the equipment prop-

erly and prevent currents

from flowing to the encoder

FG.

Errors are being caused by

excessive vibration or

shock on the encoder.

There are problems with mechani-

cal vibration or motor installation

(such as the mounting surface pre-

cision, attachment, or axial mis-

alignment).

Reduce the mechanical vi-

bration or correct the Servo-

motor’s installation.

The machine and the Ser-

vomotor are resonating.

Check whether the machine is res-

onating.

•

Readjust the Torque Com-

mand Filter Time Constant.

•

If there is resonance, set

the Notch Filter 1 Frequen-

cy (Pn1D) and Notch Filter

1 Width (Pn1E).

Symptom

Probable cause

Items to check

Countermeasures