2. System Overview

The Olink Signature Q100 system includes optical, thermal cycling, and software components necessary to perform

protein expression analysis using proximity extension assay technology.

The Olink Signature Q100 system provides throughput for proteomics that is higher by orders of magnitude than

conventional platforms using Integrated Fluidic Circuits (Chip; from now on referred to as chips)—nanofluidic circuits

containing fluidic networks that automatically combine sets of samples with sets of primers. This innovative solution for

real-time PCR provides experiment densities far beyond what is possible with microplate platforms, significantly reducing

the number of liquid-handling steps and volumes per reaction.

2.1 Components of Olink Signature Q100

The Olink Signature Q100 system has a built-in computer that controls instrument operation and monitors its

performance. The onboard computer is operated only through the touchscreen.

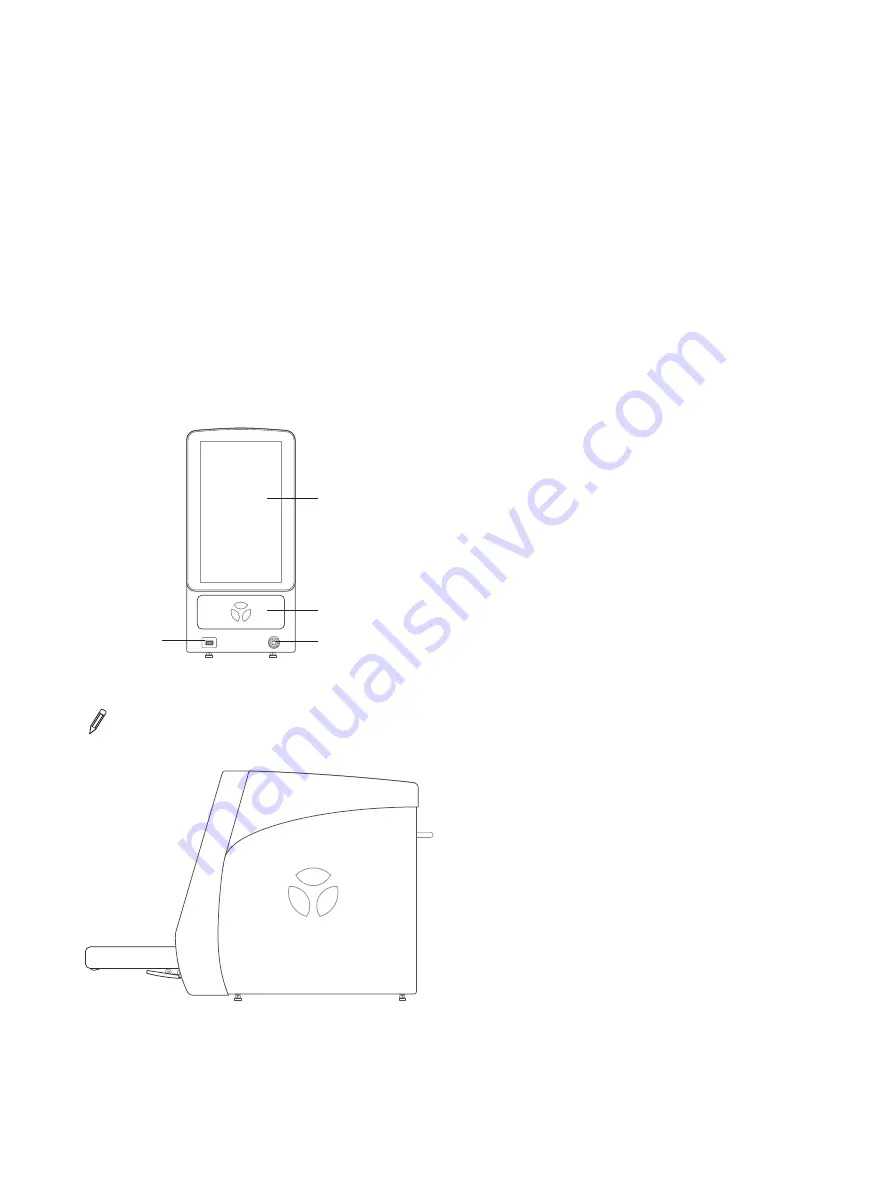

Touchscreen

Drawer (retracted)

Power button

USB 3.0 port

Figure 1. Olink Signature Q100 front view

NOTE:

The port on the front of the instrument supports USB 3.0. We recommend using a USB drive compatible

with USB 2.0 or higher.

Olink Signature Q100 side view

5