32

Electrical installation

MSD Single-Axis System Operation Manual AC-AC Servo Drive

ID no.: CA65642-001 06/2018

moog

4.8 Connection of the supply voltages

The supply of power to the MSD Servo Drive is separate for the control section and

power section. The control supply is always to be connected

first

in the sequence

so that the operation of the MSD Servo Drive can be checked first and the device

parameters configured for the planned application.

CAUTION! Damage to the device due to incorrect operation!

•

Carelessness can cause damage to the device.

Only when the mains voltage has been pre-set in the device firmware and the device has been

restarted (if the mains voltage or switching frequency has been changed) may the mains power

supply for the supply for the power section be activated.

4.8.1

Connection of the control section supply (+24 V DC)

DANGER Risk of injury due to electrical power!

•

Carelessness will result in serious injuries or death.

A dangerous voltage may be present at the device, even if the device does not emit any visual or

audible signals/indications (e.g. with mains voltage applied to terminal X11 and missing control

24 V DC on X9/X10 or X44)!

Prior to working on the device, it is therefore necessary to check there is no supply of electrical

power on X11.

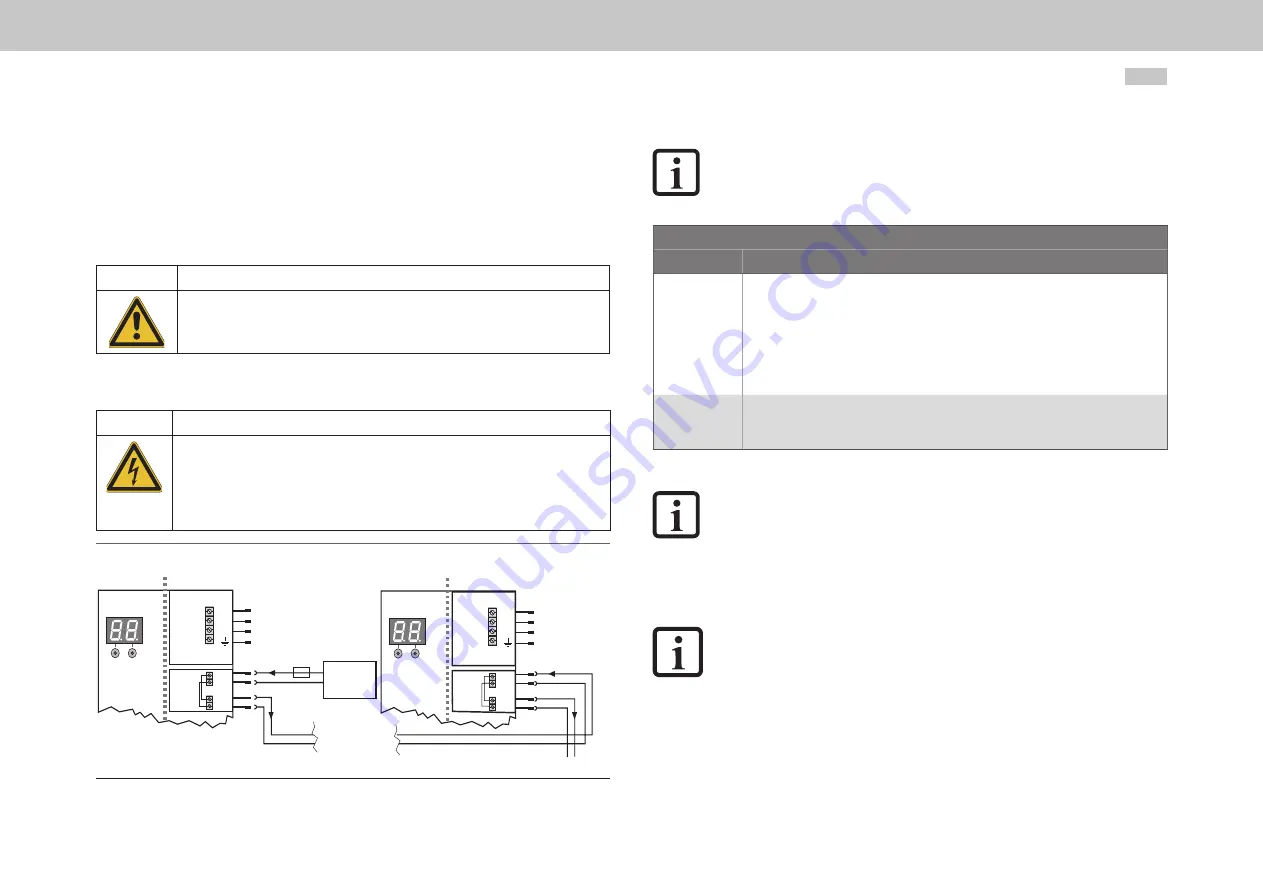

L1

L2

L3

Mains, three-phase

+24 V DC ±20%

external voltage

supply

D1 D2

Mains, three-phase

next servo drive

maximum 10 A gG

Looping possible

Observe total power

consumption!

1

2

1

2

L1

L2

L3

D1 D2

1

2

1

2

+

-

+

-

+

-

+

-

Top side

Top side

Device 1

Device 2

X11

X9

X10

X11

X9

X10

Figure 4.14 Connection of control supply, Size 1 to Size 6A

NOTE:

Suitable measures must generally be applied to provide adequate cable

protection. You will find information on the connection of the control supply for

Size 7 in Table 4.5

Control supply, Size 1 to Size 6A

Terminal/pin

Specification

X9/1 = +

X9/2 = -

•

U

V

= +24 V DC ±20 % (Size 5 to Size 6A +20/-10 %), stabilised and smoothed

•

For information on the current required for the control supply see Table A.17.

•

Continuous current carrying capacity of the terminal maximum 10 A (Size 5 to Size 6A

maximum 8 A), internal reverse polarity protection

•

The power supply unit used must have safe and reliable isolation in relation to the mains as

per EN 50178 or IEC/EN 61800-5-1.

•

Connected internally to X10

X10/1 = +

X10/2 = -

•

Continuous current carrying capacity of the terminal maximum 10 A (Size 5 to Size 6A

maximum 8 A)

•

Connected internally to X9

Table 4.4 Specification, control supply Size 1 to Size 6A

NOTE:

On the sizes Size 1 to Size 4, along with the control section the external 24 V

also supply the output for the motor brake. If this output is active, the current

for the control section plus the current for the motor holding brake, in addition

to any current required for digital inputs and outputs, flows via terminal X9.

Pay attention to this issue on dimensioning the power supply for the control

section and on looping through to other devices.

NOTE:

For size Size 5 the external 24 V control voltage must also be connected to

the control terminals (see Figure 4.5).

Summary of Contents for G305-170

Page 1: ...moog AC AC Servo Drive Single axis System 4 A to 450 A MSD Servo Drive Operation Manual...

Page 6: ...6 MSD Single Axis System Operation Manual AC AC Servo Drive ID no CA65642 001 06 2018 moog...

Page 82: ...82 MSD Single Axis System Operation Manual AC AC Servo Drive ID no CA65642 001 06 2018 moog...

Page 88: ...88 MSD Single Axis System Operation Manual AC AC Servo Drive ID no CA65642 001 06 2018 moog...

Page 89: ...89 MSD Single Axis System Operation Manual AC AC Servo Drive ID no CA65642 001 06 2018 moog...