5 - 1

5. INSPECTION

5. INSPECTION

WARNING

•

Before starting maintenance and/or inspection, make sure that the charge lamp is

off more than 10 minutes after power-off. Then, confirm that the voltage is safe in

the tester or the like. Otherwise, you may get an electric shock.

•

Any person who is involved in inspection should be fully competent to do the work.

Otherwise, you may get an electric shock. For repair and parts replacement,

contact your safes representative.

POINT

• Do not test the servo amplifier with a megger (measure insulation resistance),

or it may become faulty.

• Do not disassemble and/or repair the equipment on customer side.

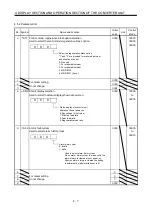

5.1 Inspection

It is recommended to make the following checks periodically:

1) Check for loose terminal block screws. Retighten any loose screws.

2) Check the servo motor bearings, brake section, etc. for unusual noise.

3) Check the cables and the like for scratches and cracks. Perform periodic inspection according to

operating conditions.

4) Check the servo motor shaft and coupling for misalignment.

5.2 Life

The following parts must be changed periodically as listed below. If any part is found faulty, it must be

changed immediately even when it has not yet reached the end of its life, which depends on the operating

method and environmental conditions.

For parts replacement, please contact your sales representative.

Part Name

Life Guideline

Smoothing capacitor

10 years

Converter unit

Cooling fan

10,000 to 30,000

hours (2 to 3 years)

Summary of Contents for Melservo-H Series

Page 11: ... 4 MEMO ...

Page 23: ...1 12 1 FUNCTIONS AND CONFIGURATION MEMO ...

Page 41: ...3 16 3 SIGNALS AND WIRING MEMO ...

Page 49: ...4 8 4 DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT MEMO ...

Page 61: ...7 6 7 OUTLINE DIMENSIONAL DRAWINGS MEMO ...

Page 81: ...9 16 9 OPTIONS AND AUXILIARY EQUIPMENT MEMO ...

Page 91: ...App 10 APPENDIX MEMO ...