6-6

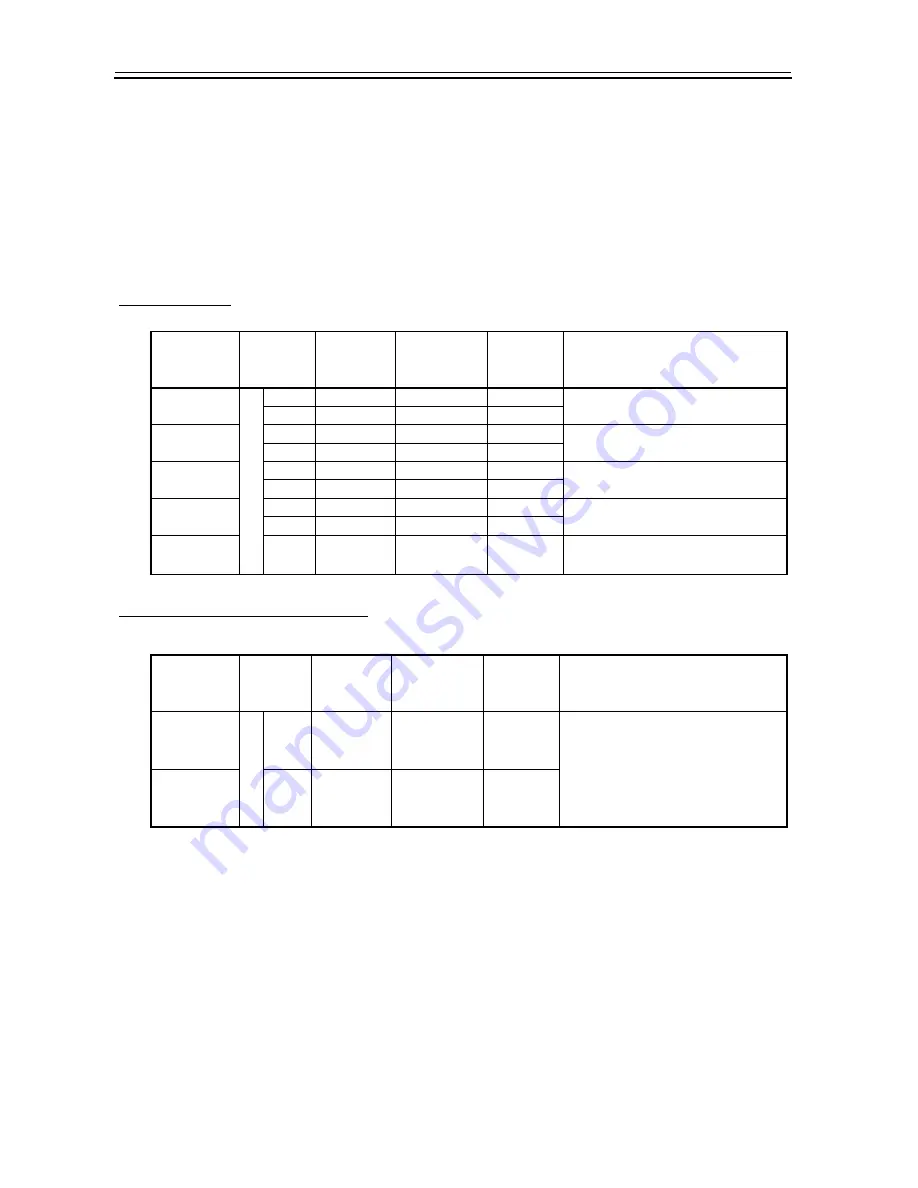

Cutting Condition Table

Depending on the type of engraving or the material to be engraved, you must change such settings as

the cutting conditions, the spindle rotating speed, and the tool. Configure the settings using values in

the table below as reference.

*1

The table is based on the engraving cutters that come with the product as supplied items. For other

types of cutters, the conditions may be different.

Engraving

Forming cut out letters

*1. The listed values are given just as an example. Make fine adjustment as needed.

Material

Tool

Cutting

depth

(mm)

Rotating

speed

(rpm)

Feed

speed

(mm/s)

Remarks

Transparent

acrylic

Engravi

ng cutte

r

0.2mm 0.1 ~0.2

14000

XY:20 Z:10

0.4mm 0.2 ~0.4

12000

XY:30 Z:10

White acrylic

0.2mm 0.1~0.15

14000

XY:15 Z:10 Soft compared to transparent acrylic

and likely to produce burrs

0.4mm 0.2~0.4

14000

XY:30 Z:10

PVC

0.2mm 0.05~0.1

14000

XY:10 Z: 5

Made of soft material and likely to pro-

duce burrs

0.4mm 0.05~0.2

14000

XY:20 Z:10

ABS

0.2mm 0.5 or less

14000

XY:20 Z: 5

0.4mm 1.1 or less

14000

XY:40 Z: 5

Metal plate

0.2mm 0.07

14000

XY:2~5

Z:2

The cutter must be used with plane

tracking sensor turned OFF.

Material

Tool

Cutting

depth

(mm)

Rotating

speed

(rpm)

Feed

speed

(mm/s)

Remarks

Acrylic plate

(2 mm thick)

S

trai

ght e

ndmil

l

φ

1~2

2.2

10000

XY: 5 Z: 5

1)3 blade is more suitable than 2 blade.

2)For PVC material, if chippings cannot

be discharged well, a high helix angle

cutter must be used.

3)Suplemental material must be used

under the workpiece.

Acrylic plate

(3 mm thick)

φ

2

2

14000

XY:15 Z:10

Summary of Contents for ME-300STII

Page 12: ...12 Machine Specification 6 10 Interface Specification 6 11 Supported G code List 6 12...

Page 26: ...2 2 Operation Panel The names and functions of the operation panel components are as follows...

Page 68: ...4 14...

Page 69: ...5 1 CHAPTER 5 ERRORS AND SOLUTIONS...

Page 76: ...5 8...

Page 77: ...6 1 CHAPTER 6 APPENDIX...

Page 89: ......