3

b) The wrench provided is for tightening screws

during "Required Daily Testing".

c) Use only identical replacement parts recom-

mended by the manufacturer.

•Use only the air tool lubricants supplied with the

tool or specified by the manufacturer.

Do not use

other lubricants; they will damage the tool. See "Ac-

cessories" for a list of recommended air tool lubricants.

AIR SOURCE

•

DANGER

Do not use oxygen, combustible

gases or bottled gases as a power

source for this tool.

The tool will explode and cause

death or serious injury.

•Never connect to an air source that is capable of

exceeding 200 psi.

Over pressurizing the tool may

result in bursting, abnormal operation, breakage of

the tool or serious injury to persons. Use only clean,

dry, regulated compressed air at the rated pressure

or within the rated pressure range as marked on the

tool. Prior to using the tool, always verify that the air

source has been adjusted to the rated air pressure or

within the rated air-pressure range. Air compressors

should comply with ANSI B19.3.

SPECIFIC SAFETY INSTRUCTIONS

FOR NAILERS

•Use air supply hoses with a minimum working

pressure rating of 200 psi.

•Use pressure regulators to limit the air pressure

supplied to the tool. Set the regulators to no more

than 120 psi.

•Install only hose couplings that will allow all pres-

sure to be removed from tool when disconnected

from the source.

If the wrong fitting is installed,

pressure may remain in the tool after disconnection,

allowing it to drive a fastener, possibly causing injury.

•Prior to each use, check workpiece contact and

trigger for correct operation.

Do not disassemble or

clamp parts of the workpiece contact, trigger, or driving

mechanism. This will cause unexpected actuation,

resulting in serious injury.

•Never point the discharge area of the tool at any

body parts or at other people.

Always assume the

tool is loaded and capable of driving a fastener.

•Do not actuate the tool unless the tool is placed

firmly against the workpiece.

If the tool is not in con-

tact with the workpiece, the fastener may be deflected

away from your target.

•Do not engage in horseplay.

The discharged fasten-

ers are projectiles capable of causing serious injury.

•When using the tool, ensure the workpiece contact

is securely placed on the workpiece.

Hold the tool

firmly and be prepared for the recoil.

•Do not remove, tamper with, or otherwise cause

the tool operating controls to become inoperable.

This will cause unexpected actuation, resulting in

serious injury.

•Do not operate a tool if any portion of the tool

operating controls is inoperable, disconnected,

altered, or not working properly.

This will cause

unexpected actuation, resulting in serious injury.

•Always keep hands and body away from discharge

area of the tool.

Never attempt to clear a jammed

workpiece contact by grasping the discharge area of

the tool. Fasteners discharged from tool can cause

serious injury if they contact hands or body.

•Do not drive fasteners close to the edge of the

workpiece.

Fasteners can slip off corners and edges

or penetrate through thin material, making them pro-

jectiles capable of causing serious injury.

•Use the tool only for the intended purpose. Do

not abuse the tool.

Do not use as a hammer, stamp

or engrave information onto parts, drop or impact the

tool or otherwise apply excess force to the tool in

use. Do not mount the tool to stands or modify it for

stationary use.

•Do not carry tool by the air hose.

Only carry the

tool by the handle with your finger off of the trigger.

•Do not use this tool without the safety warning

label in place.

If the label is damaged or missing,

contact MILWAUKEE for a free replacement.

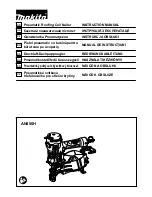

FUNCTIONAL DESCRIPTION

1

2

3

4

5

6

7

8

14

15

11

13

10

12

16

9

1. No-mar pad

2. Toe-nail claw (not shown)

3. Workpiece contact

4. Depth of drive adjustment

5. Exhaust deflector

6. Actuation selector

7. Trigger

8. Rafter hook

9. 3/8" NPT quick connector

10. Nameplate (on top of magazine)

11. Nail stop tab

12. Extra no-mar pad storage (on back of magazine)

13. Warning label (on top of magazine)

14. Pusher

15. Pusher release button

16. Nail guide

SYMBOLOGY

Read operator's manual

Wear eye protection

Keep hands away