72 Panel Functions

________________________________________________________________________________________________

_______________________________________________________________________________________________

MICROPLEX

Operator’s Manual SOLID T4 / T5 / T6 / T8

Edition 2.0

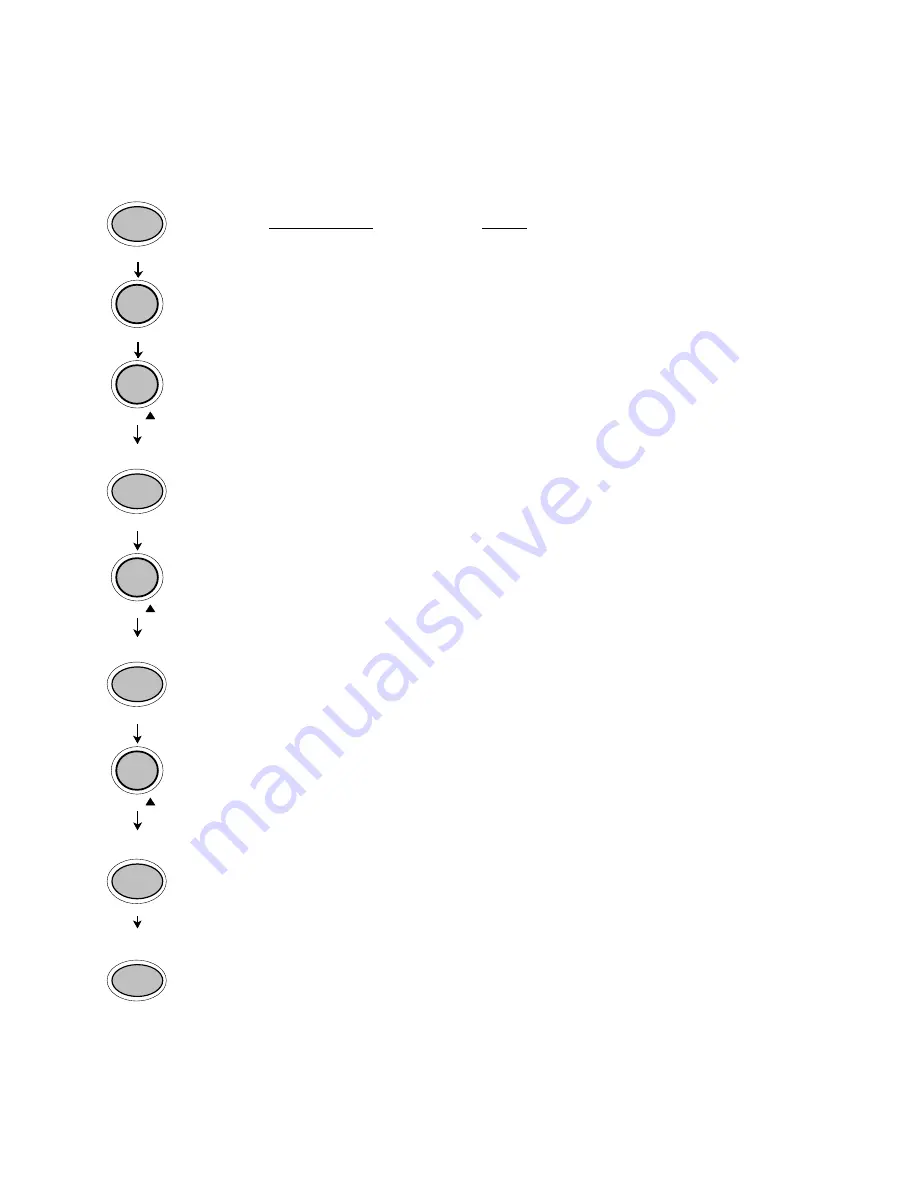

6.21. Symbol Code Selection

This function selects the active symbol code.

ON LINE

↵

PROG ESC

FEED

Ù

ON LINE

↵

FEED

Ù

ON LINE

↵

FEED

Ù

ON LINE

↵

ON LINE

↵

Panel display

[ON LINE ]

[OFF LINE ]

[Menu Level 1 ]

[Page Menu ]

[Font Number ]

[Symbol Code ]

[902, IBM PC-II ]

[901, IBM PC-I ]

[901, IBM PC-I ]

Notes

Turn the printer OFF LINE with this

key.

The PROG ESC key gives the user

access to the menu structure.

Press the FEED

s

or CUT

t

key until

[Page Menu ] is displayed.

Press the FEED

s

or CUT

t

key until

[Symbol Code ] is displayed.

Press the FEED

s

or CUT

t

key until

the desired symbol code is

displayed.

The symbol code 901, IBM PC-I is

selected.

Turn the printer ON LINE again:

Press the ON LINE

↵

key longer

than 2 seconds.

Summary of Contents for LOGIJET T4

Page 108: ......