28

Part Number 020002365 08/25/2015

Installation

Section 2

PRE-CHARGED REFRIGERATION LINE REQUIREMENTS

Important

If you have a MAC Multi-Pass condenser, please add

three (3) pounds additional charge.

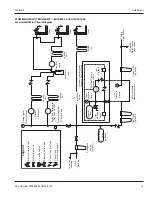

1. Both the discharge and liquid remote condensing lines

must be kept to a minimum distance for maximum

performance. All Multiplex systems are capacity

rated to 100 ft (30.5 m) tubing distance between

the compressor and condenser. If you have another

brand condenser, please add additional charge for the

condenser (example: up to three (3) pounds for a MAC

condenser).

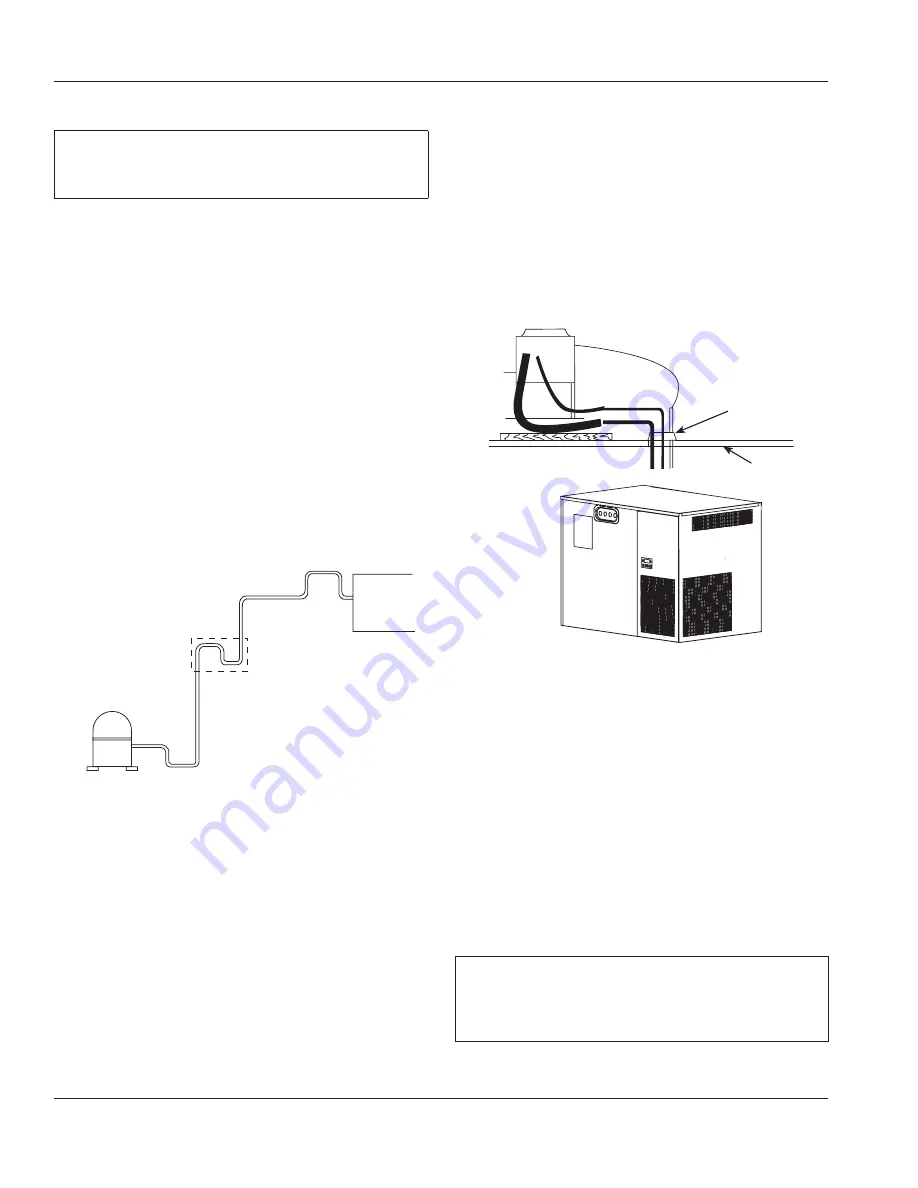

2. Any vertical rise 25 ft (7.6 m) or greater must have a

manufactured or installed trap (bend), in the discharge

refrigeration line from the compressor to the remote

condenser. A trap is necessary for every additional 25 ft

(7.6 m) vertical rise. When excessive vertical rise exists,

this trap allows oil to reach the condenser and return to

the compressor.

3. The easiest method to create a trap is to bend the

tubing (smoothly, no kinks) into the trap form.

Discharge Line

Condenser Trap

To the

Condenser

Discharge Line Trap Every

25 Vertical ft. (7.6 m)

3" (7.6 cm) x 6" (15.2 cm)

Maximum Trap Area

3 ft (0.9 m) (minimum) of Discharge

Line Trap at the Compressor

Compressor

4. The trap(s) must be of minimum height of 3" (7.6

cm) and a width of 6" (15.2 cm) to minimize oil

accumulation. The traps can also be bent out of the

refrigeration tubing. Carefully bend the tubing down

12" (30.5 cm), and then sweep the tubing back up.

5. It is critical that the Multiplex remote condensing line

size specifications for the specific model be maintained.

The specifications are 1/2" discharge and 3/8" liquid

lines.

Installing the Multiplex Remote Condenser

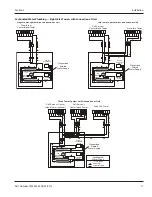

The Multiplex remote condensing units have a 208-230 Volt,

50/60 HZ, 1 PH fan motor that includes a permanent split

capacitor and internal overload protection. The electrical

wires from the refrigeration unit wire to the condenser.

The electrical installation must be in accordance with local

codes, National Electrical Code and regulations.

1. Determine a position for installation that will allow

access for maintenance and is free from obstruction.

Verify hot air discharge from other condensers does not

interfere with the inlet of this condenser.

2. Install the four legs to the sides of the condenser using

the mounting bolts provided.

3. The General Contractor or Owner must secure two

treated lumber 4" x 4" x 36" (or longer). You may then

mount the remote condenser to the treated lumber.

4. The General Contractor or Owner must install a 3" pitch

pot in the roof. Then seal for weather protection.

Roof

3" Pitch Pot

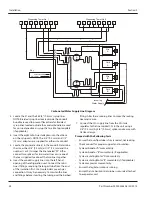

5. Locate the pre-charged refrigeration lines shipped with

the system. These lines must be a correct length for the

building design. Avoiding any kinks, neatly route these

lines from the remote condenser to the refrigeration

unit. Excess refrigeration tubing must be handled in

one of two ways. When coiling the excess tubing, make

sure the inlet to the coil is at the top of the coil and the

exit is the bottom of the coil. There can be no more

than one turn to the coil. If you have more tubing, you

must cut out the excess before connecting the ends.

When cutting the tubing, you must first evacuate the

refrigerant (line sets have a positive refrigerant holding

charge of two to three ounces). After shortening and

welding the tubing together again, you must evacuate

the tubing to 250 microns. Then recharge the tubing

with 4 ounces of appropriate refrigerant.

,

Caution

Excess refrigeration tubing must be properly cared for

before being connected to either the remote condenser

or the refrigeration unit.