Part Number 020002365 08/25/2015 27

Section 2

Installation

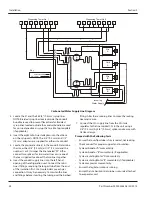

INSULATING CONNECTIONS

1. Make sure all exposed carbonated water and

syrup lines are well insulated on towers to conduit,

conduit junctions, refrigeration unit to conduits, and

drivethrough junction.

2. To insulate the above, use the leftover conduit sections

and tape.

3. Cut the conduit sections to fit snugly over the exposed

lines and fittings. A little extra time spent doing a

thorough job initially will eliminate a call back in

several days to make corrections.

NOTE: Do not inject foam material directly on the

connections where the tubing connects to the barb fittings

or directly on poly tubing.

Aerosol Foam

Chase

4. The can of foam is to be used to fill the openings

between the conduit insulation and the inside

diameter of the floor chases. The purpose is to provide

an air tight seal at the floor level to prevent foreign

matter from entering the chases. Please read the foam

manufacturer’s instructions carefully. We recommend

using the adapter with the right angle extension.

5. Insert the adapter into the openings approximately 1"

to 2" (2.5 to 5.1 cm) while depressing the adapter.

6. Move the extension around throughout the area

where the foam is to be placed. Do not over fill, allow

room for expansion. If the chase opening is too deep,

insert a section of the leftover conduit insulation in the

opening prior to using the foam insulation.

Aeroquip Connection

1. Lubricate male half diaphragm and synthetic rubber

seal with refrigerant oil.

2. Thread male coupling to its proper female half by hand

to ensure proper mating of threads.

3. Use proper wrenches (on coupling body hex and its

union nut) and tighten union nut until coupling bodies

“bottom”.

NOTE: You must use a wrench on the body to keep the body

from turning while tightening the nut with the second

wrench. If the body turns excessively, the piercing seal will

be damaged.

4. Use proper wrenches to tighten an additional 1/4

turn (90°). This final 1/4 turn is necessary to ensure the

formation of a leak proof joint. Alternately, use a torque

wrench to tighten the 1/2" coupling to 40 ft-lbs and

3/8" fitting to 11 ft-lbs.

5. Leak check all your connections. If you detect any leaks,

repair and recheck.

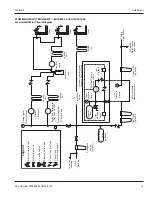

Condenser and Pre-charged Lines Installation

Before proceeding with installation, verify that all

requirements for roof mounted remote condenser units

(if applicable) have been satisfied. If unit has a remote

condenser, refer to the instructions on installing the remote

condenser supplied with the condensing unit and refer to

the section on installation of remote refrigeration line sets.

,

Caution

If you are installing a remote unit, there is a refrigeration

king valve located behind the compressor. This valve

must be back-seated prior to starting the compressor.

Failure to do so will short cycle and may damage the

compressor.

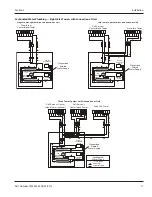

REMOTE CONDENSER REQUIREMENTS

APPROVED CONDENSERS

Multiplex Condenser - TS0895-271

MAC Multi-Pass Condensers

1. Installation and maintenance are to be performed only

by qualified refrigeration personnel. These technicians

must have EPA certification (USA), must be familiar with

local codes and regulations, and must be experienced

with this type of remote refrigeration equipment.

2. As a condition of the warranty, the check, test and

start-up procedure must be performed by qualified

personnel. Because of possible shipping damage, check

both the condensing unit and refrigeration unit(s) for

refrigerant leaks.

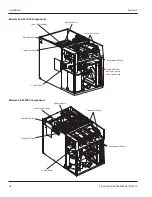

3. If the refrigeration unit is located on a roll out platform,

you must coil up to one round between the back

of the stand and the wall. This allows pull out of the

refrigeration unit for servicing.

4. If the refrigeration unit is located in a stationary

location, you must remove excess refrigeration tubing

as described below.