7.2.1.5 Checking the mechanical seal leakage (only pump sets with reinforced

bearings)

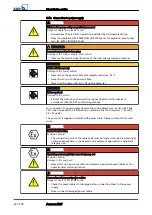

WARNING

Fluids posing a health hazard and/or hot fluids

Hazardous to persons and the environment!

▷

Collect and properly dispose of flushing liquid and any liquid residues.

▷

Wear safety clothing and a protective mask, if required.

▷

Observe all legal regulations on the disposal of fluids posing a health hazard.

NOTE

Slight wear of the mechanical seal is unavoidable. This will be aggravated by abrasive

substances contained in the fluid handled.

✓

The pump set has been placed in vertical position.

1. Place a suitable container under screw plug 903.34.

2. Remove screw plug 903.34 and joint ring 411.34.

3. Drain the leakage.

NOTE

If more than 0.25 litres of leakage should escape we recommend to replace the

mechanical seals.

4. Close screw plug 903.34 with joint ring 411.34 again.

7.2.2 Lubrication and lubricant change

7.2.2.1 Lubricating the mechanical seal

The mechanical seal is supplied with lubricant from the lubricant reservoir.

7.2.2.1.1 Intervals

Replace the lubricant after every 10,000 operating hours but at least every 3 years. (

7.2.2.1.2 Lubricant quality

The lubricant reservoir is filled at the factory with an environmentally friendly, non-

toxic lubricant of medical quality (unless otherwise required by the customer).

The following lubricants can be used for lubricating the mechanical seals:

▪

Thin-bodied paraffin oil; made by Merck, No.: 7174

▪

Merkur white oil Pharma 40; made by DEA

▪

Equivalent brand of medical quality, non-toxic

▪

Water-glycol mixture

▪

All non-doped and doped motor oils of classes SAE 10W to SAE 20W

WARNING

Contamination by lubricant of fluid handled

Hazardous to persons and the environment!

▷

Using machine oil is only permitted if the oil is disposed of properly.

Recommended quality of

lubricant

Alternative:

7 Servicing/Maintenance

42 of 78

Amarex KRT

Summary of Contents for Amarex KRT

Page 77: ......