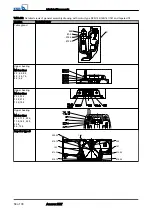

7.4.3.2.2.1 Using a special mounting and removal device

1. Screw hexagon head bolt 1 into the shaft end to prevent any damage to the

shaft thread.

2. Screw part 2 into the impeller.

3. Screw threaded bolt 3 into part 2 and pull off the impeller.

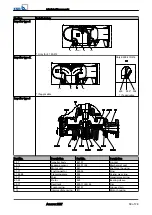

Table 22: Special mounting and removal device for removing the impeller

Size

Impeller type

Special mounting and

removal device

100-400

100-401

150-400

150-401

151-400

200-330

200-400

250-400

250-401

300-400

300-401

E, F, K

AV1

200-401

K

200-401

E

AV2

7.4.3.3 Dismantling the mechanical seal

Dismantle the mechanical seal in accordance with the general arrangement

drawings.

7.4.3.3.1 Dismantling the pump-end mechanical seal

✓

The back pull-out unit and the impeller have been removed as described above.

1. Pull the rotating assembly of mechanical seal 433.02 off shaft 210.

2. Remove discharge cover 163 from bearing bracket 330.

3. Push the stationary seat of mechanical seal 433.02 out of discharge cover 163.

7.4.3.3.2 Dismantling the motor-end mechanical seal

✓

The back pull-out unit and the impeller have been removed as described above.

1. Remove taper lock ring 515 or circlip 932.03.

2. Pull the rotating assembly of mechanical seal 433.01 off shaft 210.

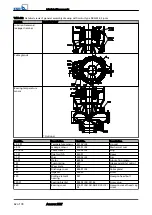

7.4.3.4 Removing the wear plate

✓

The back pull-out unit has been separated from the pump casing.

✓

The inside of the casing has been cleaned.

✓

Result of visual inspection: The wear plate needs to be replaced.

1. On transportable models, separate the pump casing from the piping.

2. Undo hexagon socket head cap screws 914.12.

3. Remove wear plate 135.01 and O-rings 412.34.

3

2

1

Fig. 24: Special mounting

and removal device

914.12

135

101

Fig. 25: Removing the

wear plate

7 Servicing/Maintenance

48 of 78

Amarex KRT

Summary of Contents for Amarex KRT

Page 77: ......