Inserting the guide wire

1. Lift clamping piece 571 and insert one end of the guide wire.

2. Run wire 59-24.01 around duckfoot bend 72-1 and back again to suspension

bracket 572 and insert it into clamping piece 571.

3. Manually tension wire 59-24.01 and secure it by means of hexagon nuts 920.37.

4. Pull the wire taut by tightening hexagon nut(s) 920.36 on the upper side of the

mounting bracket.

Observe the table "Guide wire tension".

5. Secure the nut(s) with a second hexagon nut.

6. The loose wire ends at the guide wire suspension bracket 572 can either be

twisted into a ring or the end can be cut off.

After length adjustment, tape the ends to avoid fraying.

7. Attach hook 59-18 to mounting bracket 894 for attaching the lifting chain/rope

at a later stage.

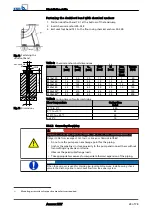

Table 11: Guide wire tension

DN

Tightening torque

M

A

[Nm]

Wire tensioning force

P [N]

50

14

6000

80

100

150

200

250

30

10000

300

5.3.1.4 Fitting the guide rail arrangement

The pump set is guided into the sump or tank along two vertical guide rails. It

attaches itself automatically to the duckfoot bend which has been fitted to the floor.

NOTE

The guide rails are not included in KSB's scope of supply.

Select guide rail materials which are suitable for the fluid handled or as specified by the

operator.

Observe the following dimensions for the guide rails:

Table 12: Guide rail dimensions

Hydraulics size

Outside diameter

[mm]

Wall thickness [mm]

6)

Minimum

Maximum

DN 40 ... DN 150

60

2

5

DN 200 ... DN 700

89

3

6

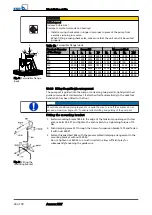

Fitting the mounting bracket

1. Fasten mounting bracket 894 to the edge of the tank/sump opening with steel

anchor bolts 90-3.37. Tighten the anchor bolts to a torque of 10 Nm.

Observe the hole pattern for the anchor bolts. (See outline drawing.)

Fig. 10: Inserting the

guide wire

90-3.37

894

Fig. 11: Fitting the

mounting bracket

6)

To DIN 2440/2442/2462 or equivalent standards

5 Installation at Site

Amarex KRT

25 of 78

Summary of Contents for Amarex KRT

Page 77: ......