CAUTION

Incomplete re-lubrication

Bearing damage!

▷

Always re-lubricate the bearings with the pump set in operation.

✓

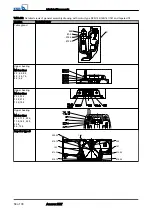

The pump set has been positioned on a level surface.

✓

The pump set is secured against tipping over.

1. Remove screw plug 903.46 and joint ring 411.46.

2. Connect the pump set to the power supply. (

CAUTION

Pump set running dry

Increased vibrations!

Damage to mechanical seals and bearings!

▷

Never operate the pump set for more than 60 seconds outside the fluid to be

handled.

3. Start up the pump set.

4. Fill in grease via lubricating nipple 636.02

5. Disconnect the pump set from the power supply again and make sure it cannot

be switched on accidentally.

6. Close screw plug 903.46 with joint ring 411.46 again.

7.3

Drainage/disposal

WARNING

Fluids posing a health hazard and/or hot fluids

Hazardous to persons and the environment!

▷

Collect and properly dispose of flushing liquid and any liquid residues.

▷

Wear safety clothing and a protective mask, if required.

▷

Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Always flush the pump if it has been used for handling noxious, explosive, hot or

other hazardous fluids.

2. Always flush and clean the pump before sending it to the workshop.

Make sure to add a certificate of decontamination. (

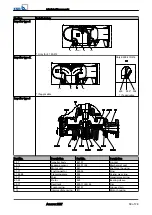

7.4

Dismantling the pump set

7.4.1 General information/Safety regulations

WARNING

Unqualified personnel performing work on the pump (set)

Risk of personal injury!

▷

Always have repair and maintenance work performed by specially trained,

qualified personnel.

WARNING

Hot surface

Risk of personal injury!

▷

Allow the pump set to cool down to ambient temperature.

Observe the general safety instructions and information.

7 Servicing/Maintenance

Amarex KRT

45 of 78

Summary of Contents for Amarex KRT

Page 77: ......