Place of installation for transportable models

WARNING

Placing the pump set on an unsecured and uneven mounting surface

Personal injury and damage to property!

▷

Always place the pump set on a solid and level surface with the pump set in

vertical position and the motor on top.

▷

Only place the pump set on a surface of sufficient load-carrying capacity.

▷

Use appropriate means to secure the pump set against overturning or tipping

over.

▷

Refer to the weights given in the data sheet/name plate.

Any resonances at the usual excitation frequencies (1x and 2x rotational frequency,

rotational noise) must be prevented both in the foundation and in the connected

piping, as such frequencies may cause extreme vibrations.

1. Check the structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing/general arrangement drawing.

5.2.3 Checking the lubricant level

The lubricant reservoirs are filled with an environmentally-friendly, non-toxic

lubricant at the factory.

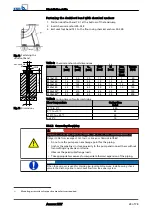

1. Position the pump set as illustrated.

903.03

411.03

903.03

411.03

Fig. 4: Checking the lubricant level

2. Unscrew screw plug 903.03 with joint ring 411.03.

⇨

The lubricant must be level with the filler opening.

3. If the lubricant level is lower, fill the lubricant reservoir via the filler opening

until the reservoir overflows. (

4. Close screw plug 903.03 with joint ring 411.03 again.

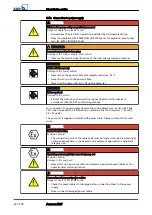

5.2.4 Checking the direction of rotation

DANGER

Pump set running dry

Explosion hazard!

▷

Check the direction of rotation of explosion-proof pump sets outside the

potentially explosive atmosphere.

Resonances

5 Installation at Site

Amarex KRT

21 of 78

Summary of Contents for Amarex KRT

Page 77: ......