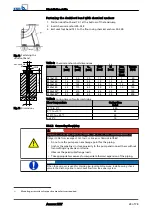

Fastening the duckfoot bend with chemical anchors

1. Position duckfoot bend 72-1 at the bottom of the tank/sump.

2. Insert chemical anchors 90-3.38.

3. Bolt duckfoot bend 72-1 to the floor using chemical anchors 90-3.38.

Table 8: Chemical anchors bolt dimensions

Bolt size

d

o

[mm]

t=h

req

[mm]

t

fix

[mm]

WAF

[mm]

M

[mm]

Hex.

head

WAF

[mm]

Torque

[Nm]

M 10x130

12

90

20

17

10

7

20

M 12x160

14

110

25

19

12

8

40

M 16x190

18

125

35

24

16

12

60

M 20x260

25

170

65

30

20

12

120

M 24x300

5)

28

210

65

36

24

-

150

M 30x380

5)

35

280

65

46

30

-

300

Table 9: Curing times of mortar cartridge

Floor temperature

Curing time

[min]

-5

℃

to 0

℃

240

0

℃

to +10

℃

45

+10

℃

to +20

℃

20

> +20 °C

10

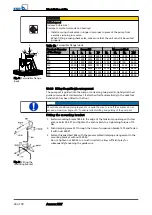

5.3.1.2 Connecting the piping

DANGER

Impermissible loads acting on the flange of the duckfoot bend have been exceeded

Danger to life from leakage of hot, toxic, corrosive or flammable fluids!

▷

Do not use the pump as an anchorage point for the piping.

▷

Anchor the pipelines in close proximity to the pump and connect them without

transmitting any stresses or strains.

▷

Observe the permissible flange loads.

▷

Take appropriate measures to compensate thermal expansion of the piping.

NOTE

When the pump set is used for draining low-level building areas, install a swing check

valve in the discharge line to avoid backflow from the sewer system.

Fig. 6: Fastening the

duckfoot bend

t

=

h

req

t

fix

WAF

M

Hex. Head WAF

do

l

Fig. 7: Dimensions

5)

Mounting accessories of respective manufacturer required.

5 Installation at Site

Amarex KRT

23 of 78

Summary of Contents for Amarex KRT

Page 77: ......