7.2

Servicing/inspection

KSB recommends the following schedule for pump set maintenance:

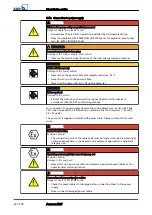

Table 15: Overview of maintenance work

Maintenance interval

Maintenance work

For details see ...

After 4,000 operating hours

7)

Insulation resistance test

Check the power cables

Visually inspect the lifting chain/rope

After 10,000 operating hours

8)

Check the sensors

Check the mechanical seal leakage

Change the lubricant

Lubricate the bearings

Every five years

General overhaul

7.2.1 Inspection work

7.2.1.1 Checking the lifting chain/rope

✓

The pump set has been pulled out of the pump sump and cleaned.

1. Inspect the lifting chain or rope as well as the attachment for any visible damage.

2. Replace any damaged components by original spare parts.

7.2.1.2 Checking the power cables

✓

The pump set has been pulled out of the pump sump and cleaned.

1. Inspect the power cable for any visual damage.

2. Replace any damaged components by original spare parts.

✓

The pump set has been pulled out of the pump sump and cleaned.

1. Measure the resistance between earth conductor and earth.

The resistance measured must be less than 1

Ω.

2. Replace any damaged components by original spare parts.

DANGER

Defective earth conductor

Electric shock!

▷

Never switch on a pump set with a defective earth conductor.

7.2.1.3 Measuring the insulation resistance

Measure the insulation resistance of the motor winding during annual maintenance

work.

✓

The pump set has been disconnected in the control cabinet.

✓

Use an insulation resistance measuring device.

✓

The max. measuring voltage is 1000 V.

1. Measure winding against earth.

To do so, connect all winding ends together.

2. Measure the winding temperature sensor against earth.

To do so, connect all core ends of the winding temperature sensors together and

connect all winding ends to earth.

Visual inspection

Checking the earth

conductor

7)

At least once a year

8)

At least every three years

7 Servicing/Maintenance

40 of 78

Amarex KRT

Summary of Contents for Amarex KRT

Page 77: ......