903.03

411.03

903.03

411.03

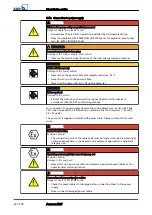

Fig. 21: Filling in the lubricant

2. Pour lubricant into the lubricant filler opening until the lubricant reservoir

overflows.

3. Close screw plug 903.03 again with a new joint ring 411.03.

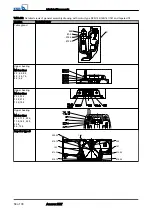

7.2.2.2 Lubricating the rolling element bearings

The rolling element bearings of the pump sets are grease-packed and maintenance-

free, with the exception of those described below.

On pump sets with reinforced bearings (

Section 4.4 Page 16) the pump-end rolling

element bearings can be re-lubricated. Relubricate these bearings as part of the

maintenance work.

7.2.2.2.1 Grease quality

The following greases can be used to lubricate the rolling element bearings:

▪

Lithium soap grease suitable for high temperatures

▪

ESSO UNIREX N3

▪

FAG ARCANOL L40

▪

TEXACO HYTEX EP3/DEA Pragon

7.2.2.2.2 Grease quantity

Use 60g grease to lubricate the rolling element bearings.

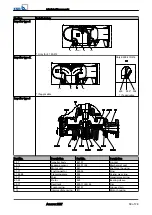

7.2.2.2.3 Re-lubrication

An encapsulated water-tight lubricating nipple allows re-lubrication of the angular

contact ball bearings without opening the pump.

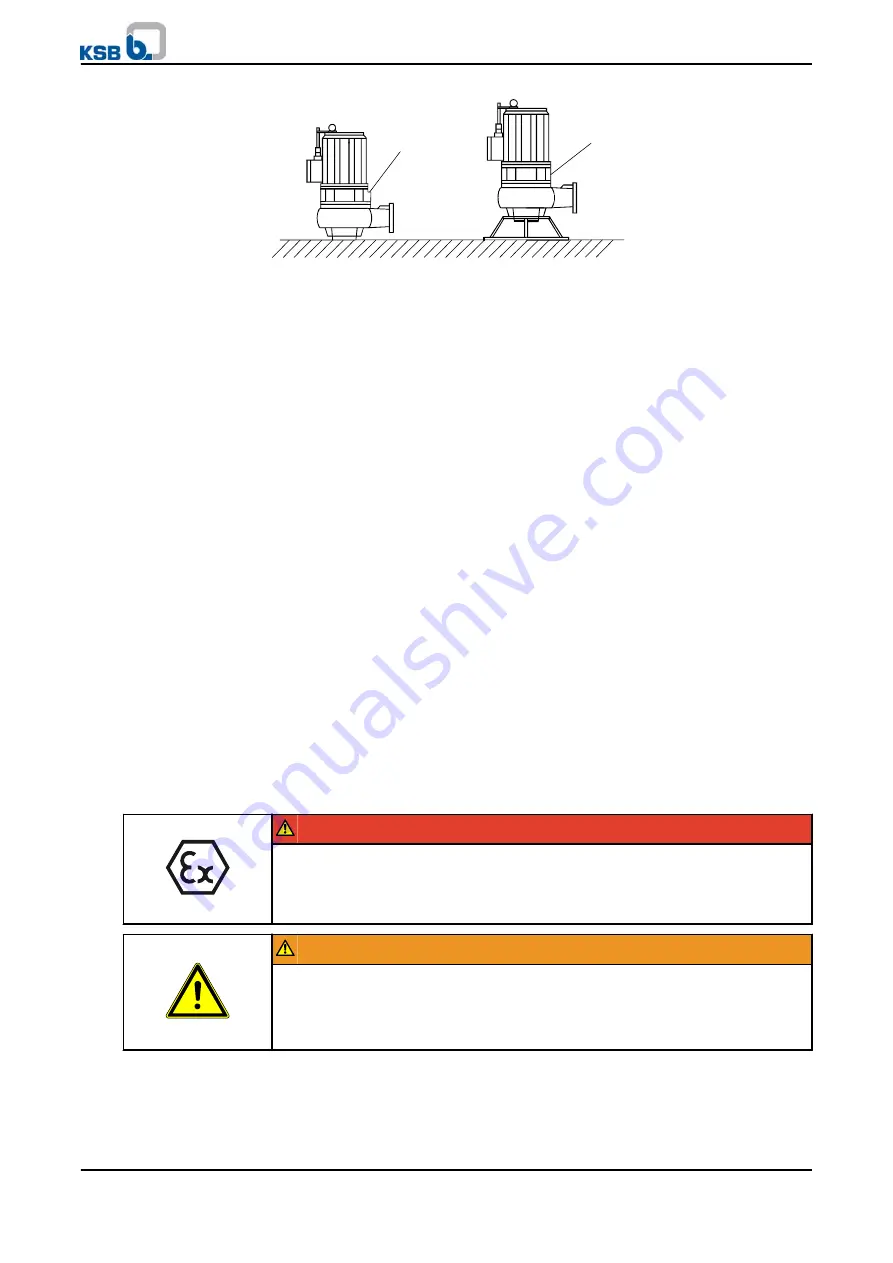

DANGER

Dry running

Risk of explosion!

▷

Re-lubricate explosion-proof pump sets outside potentially explosive

atmospheres.

WARNING

Hands or objects inside the pump casing

Risk of injuries, damage to the pump!

▷

Never insert your hands or any other objects into the pump.

▷

Check that the inside of the pump is free from any foreign objects.

Grease quality

Recommended

commercially available

brands

Pump sets with reinforced

7 Servicing/Maintenance

44 of 78

Amarex KRT

Summary of Contents for Amarex KRT

Page 77: ......