• When the oil inside the swing motor case is drained

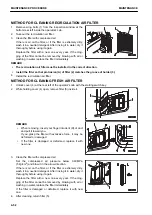

1) Run the engine at low idle, loosen the hose (4) at port

S, and check that oil oozes out from the port S hose

(4).

NOTICE

At this time, do not perform the swing operation.

2) If oil does not ooze out, stop the engine, remove the

port S hose (4), and fill the motor case with hydraulic

oil.

3) After completely bleeding the air from the swing motor,

tighten the port S hose (4).

4) Run the engine at low idle and slowly swing at least 2 turns uniformly to the right and left.

NOTICE

• If the air is not bled from the swing motor, the motor bearings may be damaged.

• Perform the air bleeding according to the above procedure when the swing motor safety

valve is replaced.

5.

Bleeding air from attachment (when installed)

If an attachment is installed, operate the attachment pedal repeatedly (approximately 10 times) with the en-

gine running at low idle until the air is completely bled from the attachment circuit.

NOTICE

• If the attachment has its own air bleeding procedure specified by the manufacturer, observe

them.

• After completing the air bleeding operation, stop the engine, leave the machine as it is for 5 mi-

nutes or longer, and then start the operation again. This will remove the air bubbles in the oil

inside the tank.

• Check for oil leakage and wipe off any spilled oil.

6.

Bleeding air from travel motor circuit

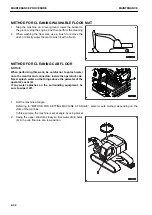

If the piping of the travel motor is removed once and as-

sembled again afterwards, run the engine at low idle, and

perform the following to bleed air from the circuit.

1) Start the engine, and run it at low idle.

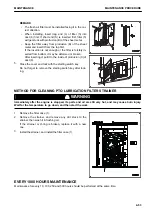

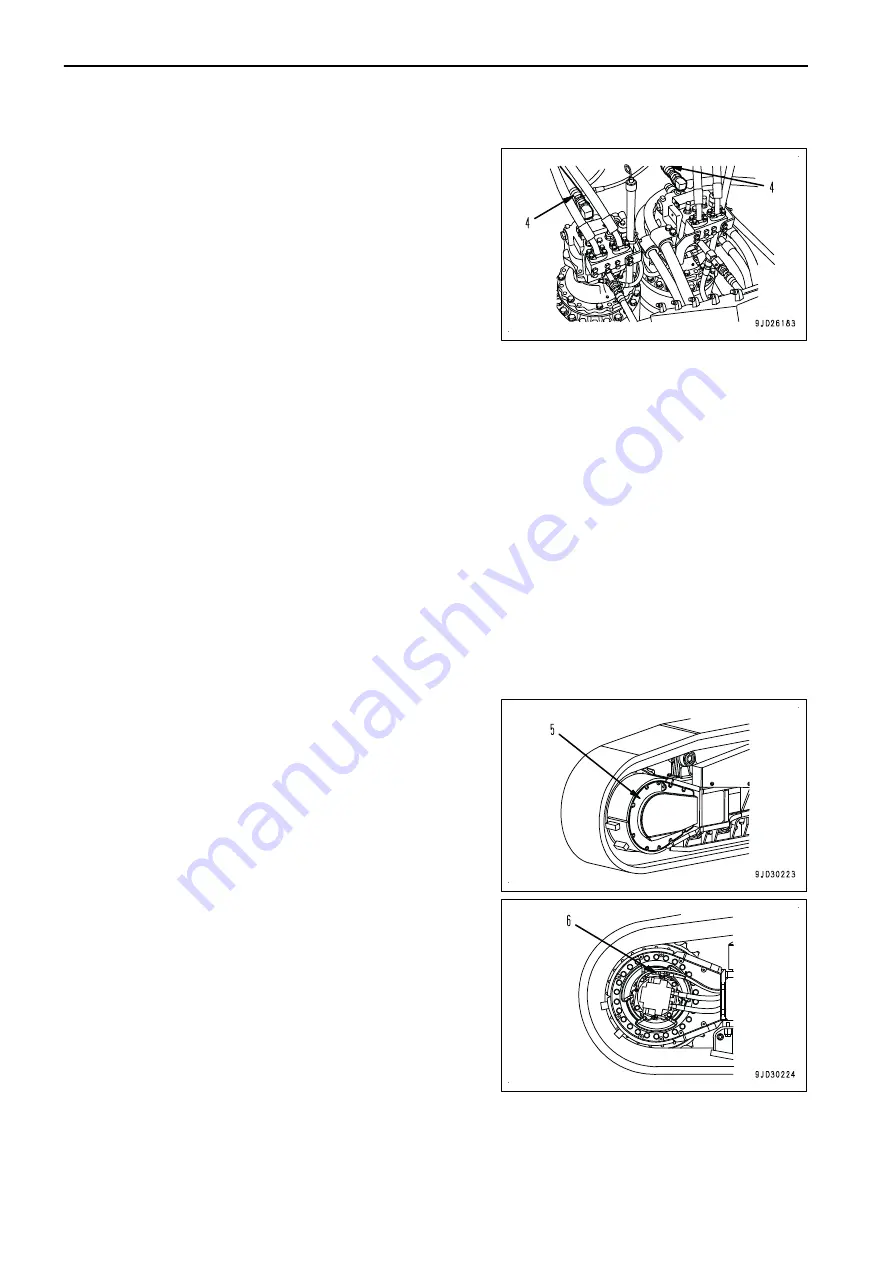

2) Remove the travel motor cover (5), and loosen the air

bleeding plug (6) 1 turn.

NOTICE

Never loosen the plug (6) more than 1 turn.

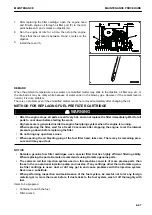

3) When oil which is not milky white comes out through

the air bleeding plug (6), tighten the air bleeding plug

(6).

4) Operate the fine control of the travel lever forward and

reverse for 4 to 5 times.

5) Install the travel motor cover (5).

7.

Operating

1) After completing the air bleeding, stop the engine,

leave the machine as it is for 5 minutes, and then start

the operation. This will remove the air bubbles in the

oil inside the tank.

2) Check that there is no leakage of oil and wipe off any oil that is spilled.

MAINTENANCE PROCEDURE

MAINTENANCE

4-38

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......