89

9.0 Editing Placed Objects

All of the toolbar items depicted below are also available from the Edit menu. If tool bars are not visible, use the View Menu

to call them up.

Standard Windows editing functions

Undo,

Redo,

Cut,

Copy,

Paste

and

Delete

are available for all

objects.

9.1 Moving and Resizing Objects

To move and resize drawing objects: Use the pointer to select the object by clicking on it. Drag a rectangle around

a group of objects to select them. Optionally, hold the

Ctrl

key down and click one at a time on the objects to move.

The object or group’s handles appear. The object or group can now be dragged around the window. A single object

can be resized by dragging its handle.

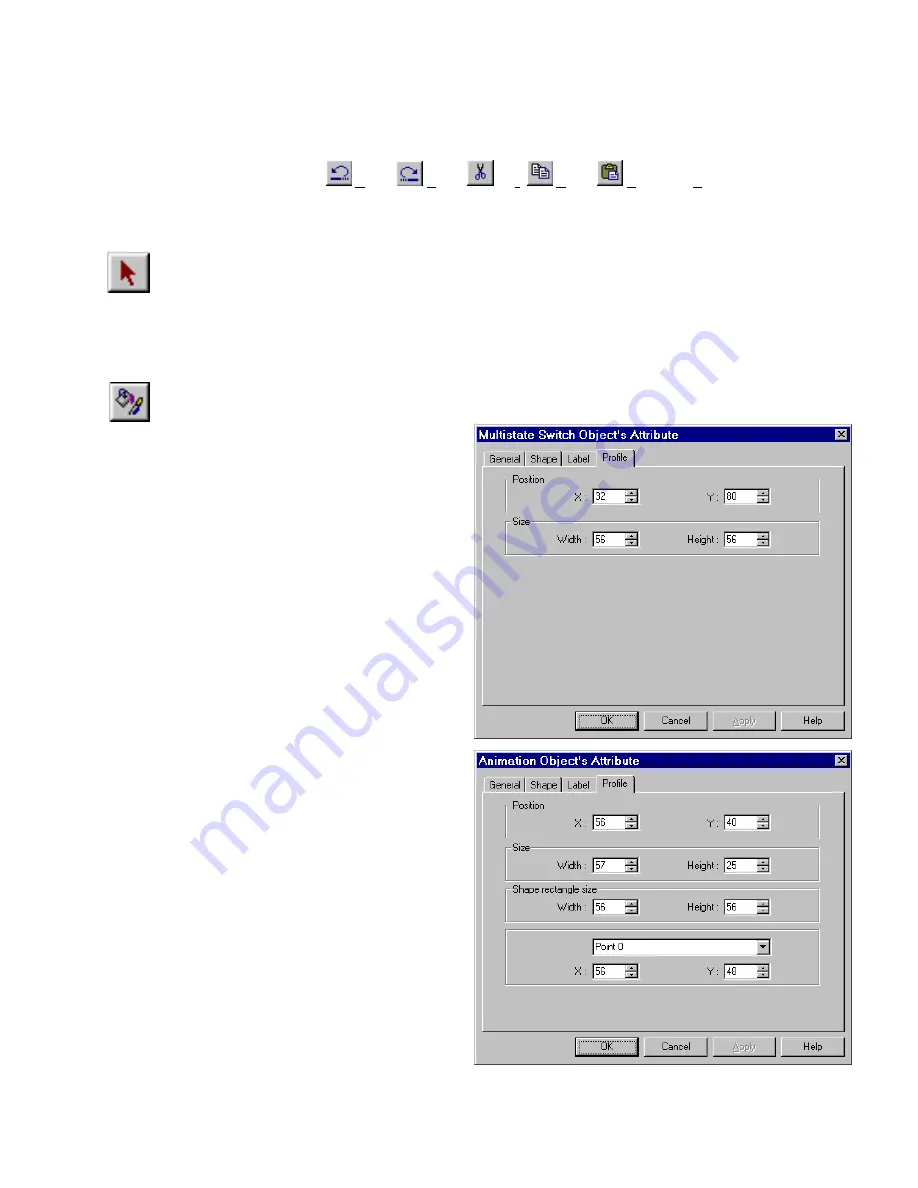

9.1.1 The Profile Tab

Once an object is placed on the window, its position can be set to a numerical position through the profile tab of the

Attributes Dialog for that part (object). Click on the Edit icon and adjust the Profile Tab settings as desired.

Position:

X

and

Y

are the location of the upper left

corner of the object.

Size:

Width

and

Height

are the overall size of the

object in pixels.

Note:

The following parts do not have Profile tabs:

Numeric Input Extend

ASCII Input Extend

ASCII Data

Alarm Display

Alarm Bar

Recipe Display

Event Display

The Animation Parts have additional fields as described

below.

Shape rectangle size:

Width

and

Height

are the overall size of the Shape

or Bitmap assigned to the part in pixels.

Below this are fields for setting the

X

and

Y

location each

Point

along the animation path. (See Animation in the

Object Reference Guide for more details.)

Summary of Contents for MMI-1500

Page 2: ...ii...