Safety

Precautions for Maintenance

●

Upon detection of any visible damage on

the appearance, please replace the

“periodically replaced critical safety parts”,

even if the designated replacement period

is not reached.

1-33

Jumper Start with Battery Charging Cable

●

To start the engine by battery charging

cable, ensure to connect the cable correctly

as per following procedure. The incorrect

connection of cable can cause discharging

and battery explosion.

●

Keep the “Malfunctioned machine” and

“Rescue machine” away from mutual

contact.

●

Never touch the positive (+) and negative

(-) electrodes of battery charging cable

with each other or with the machine.

●

During connection, firstly connect the

positive electrode of battery charging cable

to

positive

(+)

terminal.

During

disconnection, firstly disconnect the

negative (-) terminal (grounding terminal)

from the negative cable.

●

Ensure to connect the cable clamps

securely.

●

Connect the last clamp of battery charging

cable to a place as far as possible from the

battery.

●

To start the engine with battery charging

cable, always wear goggles and gloves.

●

Use the battery charging cable and clamps

of dimensions suitable to the battery

capacity. Never use damaged or corroded

battery charging cable or clamps.

●

Ensure that the battery capacity is same for

the “Malfunctioned machine” and “Rescue

machine”.

Asking Ken stone Heavy Machinery Service

Dealer for Welding Repair

The welding operations, if necessary, must be

fulfilled by competent personnel in a working

site with complete equipment. To prevent

damaging any machine part by over-high

current or electric spark, please abide by the

following precautions.

●

Disconnect the battery cables before

electric welding.

●

Do not apply 200V or higher voltage

continuously.

●

Connect the grounding point within 1m

reach from the welding area. Do not

connect the grounding terminal near the

electronic control device/instrument or

connector.

●

Ensure there is no seal ring or bearing

between welding area and grounding

terminal.

●

Do not connect the grounding terminal to

Summary of Contents for XN10-8

Page 9: ...Safety 1 1...

Page 44: ...Safety Safety Signs 1 36...

Page 49: ...Controls 2 1...

Page 55: ...2 7 Records...

Page 64: ...Operations 3 1...

Page 87: ...Operations Parking of This Machine Locking Ensure to lock the following parts 3 24...

Page 93: ...Transportation 4 1...

Page 97: ...Transportation Lifting of Machine 4 5 unit mm...

Page 99: ...Maintenance 5 1...

Page 112: ...5 14 Records...

Page 120: ...5 22 Records...

Page 130: ...5 32 Records...

Page 132: ...5 34 Records...

Page 144: ...Troubleshooting 6 1...

Page 155: ...Parameters 7 1...

Page 159: ...Parameters Lifting power 7 5...

Page 160: ...7 6 Records...

Page 161: ...Optional products 8 1...

Page 170: ...8 10 Records...

Page 172: ...Optional products Canopy 8 12...

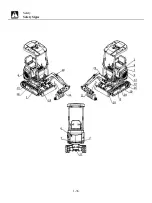

Page 173: ...Parts number position Upper frame number 20060001 8 13...