42

SRKA4/ISP4400 Server System Product Guide

Each power subsystem auto-senses within the following voltage ranges and is rated as follows:

•

100-120 V

∼

at 50/60 Hertz (Hz); 11.0 A maximum

•

200-240 V

∼

at 50/60 Hz; 5.5 A maximum

The DC output voltages of each power supply module are:

•

+3.3 V at 28 A max (Total combined power of the +3.3 and +5 channels must not exceed

195W)

•

+5 V at 32 A max (Total combined power of the +3.3 and +5 channels must not exceed 195W)

•

+12 V at 12.0 A with 15.0 A peak

•

-12 V at 0.5 A

•

+5 V standby at 2 A whenever AC power is supplied to the server system

The DC output voltages of the power subsystem with two or three modules are:

•

+3.3 V at 50 A max (Total combined power of the +3.3 and +5 channels must not exceed

351W)

•

+5 V at 58 A max (Total combined power of the +3.3 and +5 channels must not exceed 351W)

•

+12 V at 22.0 A with 28.0 A peak

•

-12 V at 0.5 A

•

+5 V standby at 2 A

DC power is sourced through a 20-pin and 24-pin power cables to the baseboard. Remote sensing

signals are provided through one 14-pin auxiliary power cable to the baseboard.

The AC power status of each power supply module is indicated by an LED. The LED is located on

the power supply module.

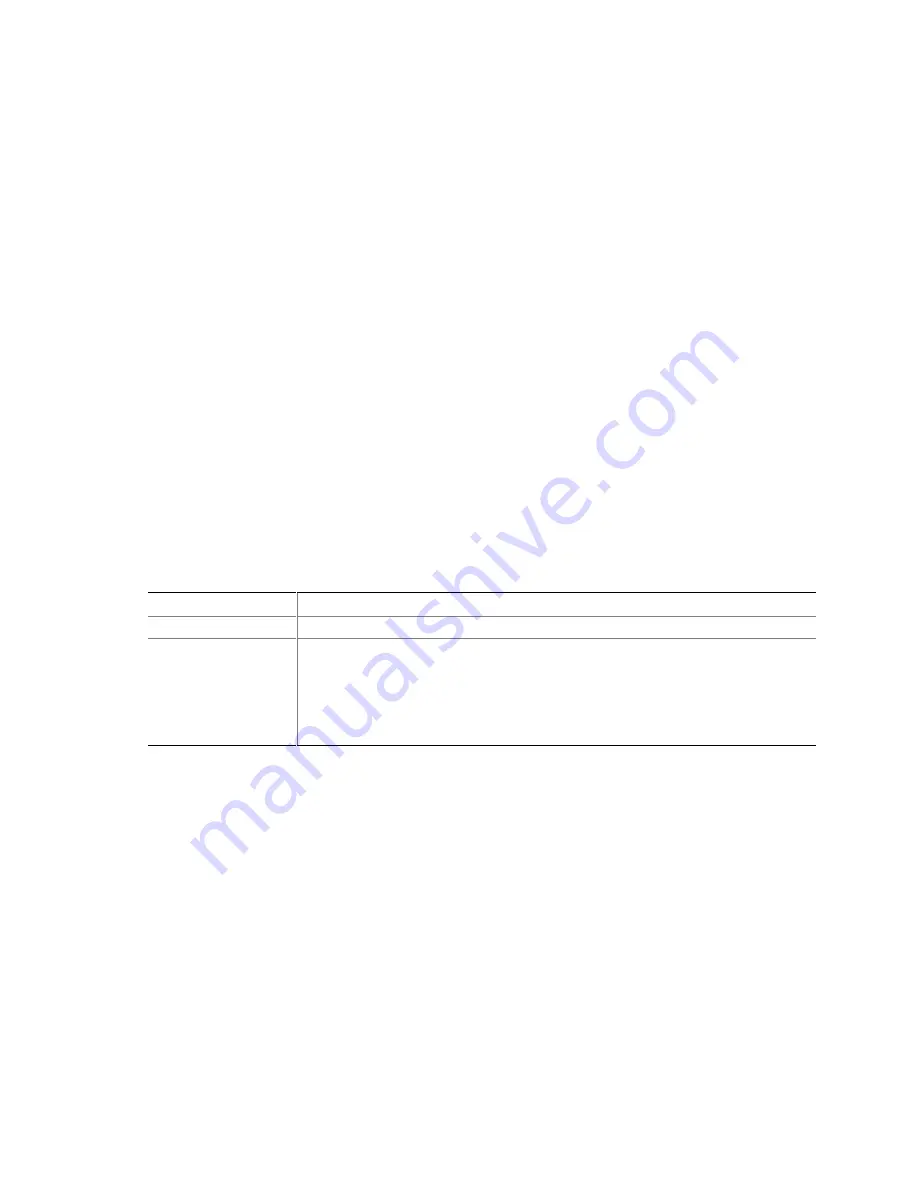

LED State

Status

Solid green

AC power is applied to the power subsystem and standby voltage is available.

Off

The LED is off when one of the following conditions occur:

•

The power supply modules are disabled by the DC enable signal.

•

The power supply module is disabled by another switch.

•

The power supply module has been overstressed.

•

The power supply module has failed and replacement of the unit is necessary.

There are also three standby channels and each has an LED called a standby LED. These LEDs

are located on the right side of the power subsystem bay and each indicates the status of that

standby channel.

In a redundant configuration, individual power supply modules are hot-swappable. In other words,

you can remove and install a power supply module without shutting down the server. After a

power supply module has been removed from the system, airflow patterns are disrupted within the

system. To maintain correct airflow patterns within the chassis and to ensure that all components

remain within specification under all system environmental conditions, it is recommended that

power supply module hot-swap operations do not exceed two minutes in duration.

Summary of Contents for ISP4400 - Server Platform - 0 MB RAM

Page 1: ...SRKA4 ISP4400 Server System Product Guide Order Number A07928 003...

Page 8: ...viii SRKA4 ISP4400 Server System Product Guide...

Page 10: ...10 SRKA4 ISP4400 Server System Product Guide...

Page 20: ...20 SRKA4 ISP4400 Server System Product Guide...

Page 22: ...22 SRKA4 ISP4400 Server System Product Guide...

Page 24: ...24 SRKA4 ISP4400 Server System Product Guide...

Page 34: ...34 SRKA4 ISP4400 Server System Product Guide...

Page 48: ...48 SRKA4 ISP4400 Server System Product Guide...

Page 70: ...70 SRKA4 ISP4400 Server System Product Guide...

Page 78: ...78 SRKA4 ISP4400 Server System Product Guide...

Page 110: ...110 SRKA4 ISP4400 Server System Product Guide...

Page 114: ...114 SRKA4 ISP4400 Server System Product Guide...