BOLTSCOPE PRO

- Bolt Tension Monitor

87

Chapter 9 Temperature Compensation

9.1 Purpose

The temperature of a fastener affects the overall physical length, as well as the

velocity of a fastener. As the temperature of a fastener increases, the ultrasonic

length increases at a rate greater than the physical change in length. If the user

intends to measure the same fastener at different time intervals over the service

life of the bolt, temperature compensation is very important to produce accurate

results. However, if a fastener will only be measured once, never to be

measured again, temperature compensation is not needed, as long as the

reference length and elongation are measured at the same temperature and

time.

The thermal expansion of the fastener and the ultrasonic change in velocity as a

result of temperature are two separate effects. However, for the purpose of the

BOLTSCOPE PRO

, they are combined in a single factor known as the

Temperature Coefficient (Tc). The sections that follow outline the procedures for

selecting and using the temperature compensation mode with the accessory

temperature sensor.

9.2 Manual Mode

The manual mode option relies on the user to enter in the current temperature

before measuring. This is useful to those users that do not require temperature

compensation, or have an external temperature device measuring the

temperature.

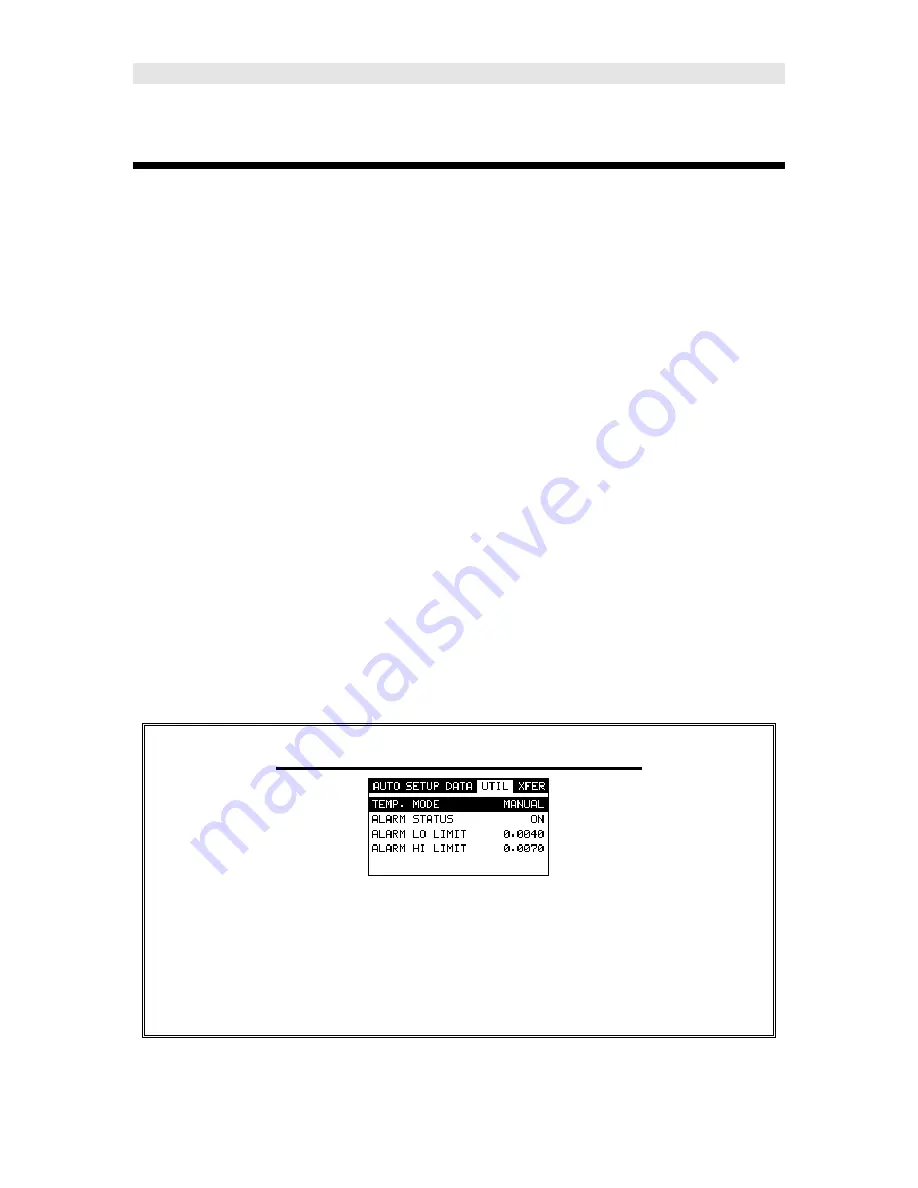

Selecting Manual Temperature Mode

1) Press the

MENU

key once to activate the menu items tab. Press the

MENU

key multiple times to tab right, and the

ESC

key multiple times to

tab left, until the

UTIL

menu is highlighted and displaying the submenu

items.