199

HEIDENHAIN TNC 426 B, TNC 430

X

Z

Q11

Q12

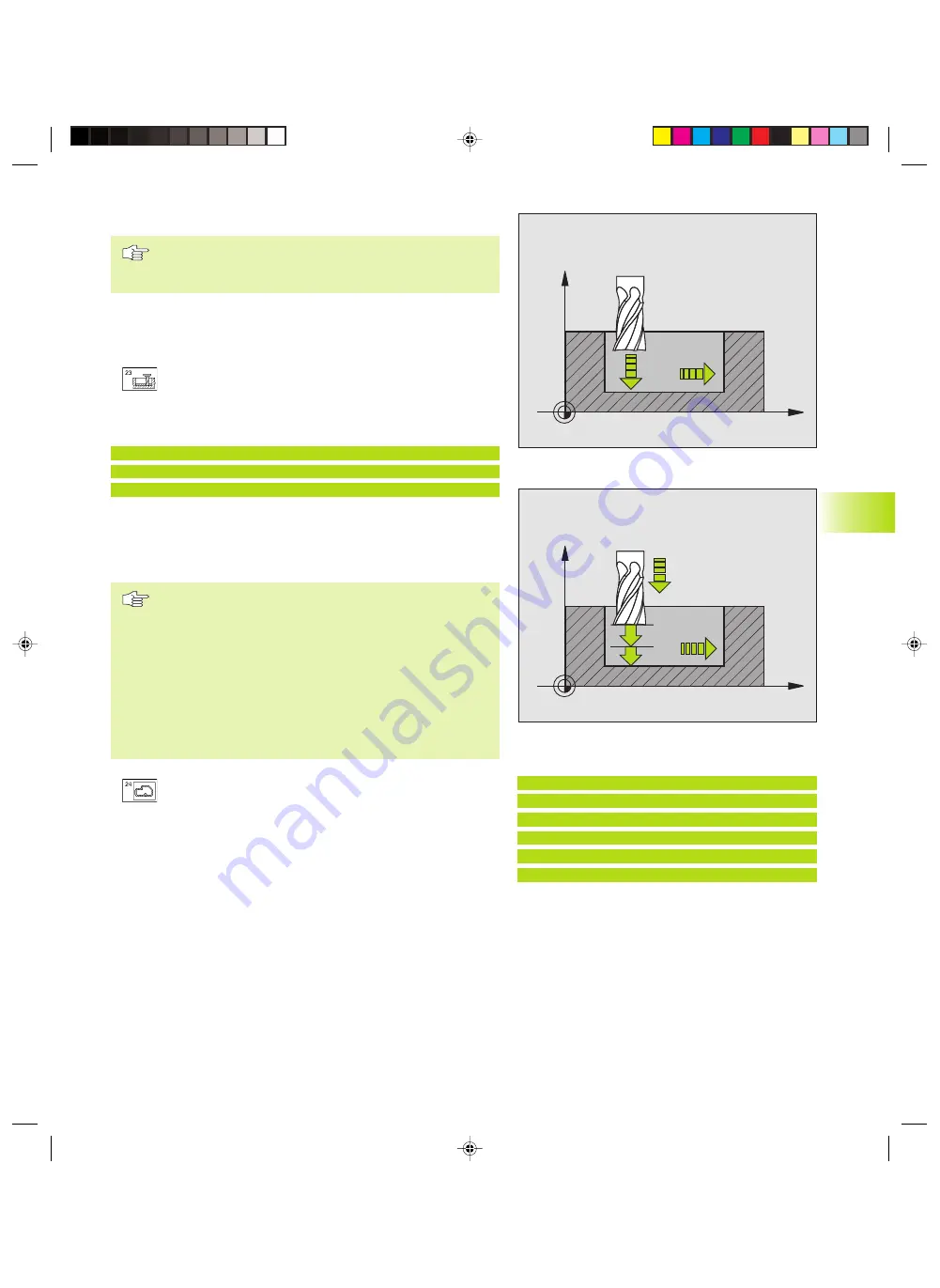

FLOOR FINISHING (Cycle 23)

The TNC automatically calculates the starting point for

finishing. The starting point depends on the available

space in the pocket.

The tool approaches the machining plane smoothly (in a vertically

tangential arc). The tool then clears the finishing allowance

remaining from rough-out.

ú

Feed rate for plunging: Traversing speed of the tool

during penetration

ú

Feed rate for milling Q12: Traversing speed for milling

Example NC blocks:

60 CYCL DEF 23.0 FLOOR FINISHING

Q11=100

;FEED RATE FOR PLUNGING

Q12=350

;FEED RATE FOR MILLING

SIDE FINISHING (Cycle 24)

The subcontours are approached and departed on a tangential arc.

Each subcontour is finish-milled separately.

Before programming, note the following:

The sum of allowance for side (Q14) and the radius of the

finish mill must be smaller than the sum of allowance for

side (Q3, Cycle 20) and the radius of the rough mill.

This calculation also holds if you run Cycle 24 without

having roughed out with Cycle 22; in this case, enter “0”

for the radius of the rough mill.

The TNC automatically calculates the starting point for

finishing. The starting point depends on the available

space in the pocket.

ú

Direction of rotation ? Clockwise = –1 Q9:

Direction of machining:

+1

: Counterclockwise

–1

: Clockwise

ú

Plunging depth Q10 (incremental value):

Dimension by which the tool plunges in each infeed

ú

Feed rate for plunging Q11: Traversing speed of the

tool during penetration

ú

Feed rate for milling Q12: Traversing speed for milling

ú

Finishing allowance for side Q14 (incremental value):

Enter the allowed material for several finish-milling

operations. If you enter Q14 = 0, the remaining

finishing allowance will be cleared.

X

Z

Q11

Q12

Q10

Example NC blocks:

61 CYCL DEF 24.0 SIDE FINISHING

Q9=+1

;DIRECTION OF ROTATION

Q10=+5

;PLUNGING DEPTH

Q11=100

;FEED RATE FOR PLUNGING

Q12=350

;FEED RATE FOR MILLING

Q14=+0

;ALLOWANCE FOR SIDE

8.5 SL Cycles

kkap8.pm6

30.06.2006, 07:03

199

www.EngineeringBooksPdf.com

Summary of Contents for TNC 426 B

Page 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Page 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Page 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Page 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Page 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Page 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Page 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Page 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Page 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Page 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Page 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Page 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Page 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Page 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Page 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Page 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...