88

5 Programming: Tools

5.5 W

o

rking with Cut

ting D

ata T

ables

Structure command Meaning

NR

Column number

NAME

Overview of columns

TYPE

N: Numerical input

C: Alphanumeric input

WIDTH

Width of column For type N

including algebraic sign,

comma, and decimal places

DEC

Number of decimal places

(max. 4, effective only for

type N)

ENGLISH

Language-dependent

to

dialogs

HUNGARIAN

(max. 32 characters)

Working with automatic speed/feed rate calculation

If it has not already been entered, enter the type of workpiece

material in the file WMAT.TAB

If it has not already been entered, enter the type of cutting

material in the file TMAT.TAB

If not already entered, enter all of the required tool-specific data

in the tool table:

■

Tool radius

■

Number of teeth

■

Tool type

■

Tool cutting material

■

The cutting data table for each tool

If not already entered, enter the cutting data in any cutting data

table (CDT file)

Test Run operating mode: Activate the tool table from which the

TNC is to take the tool-specific data (status S).

In the NC program, set the workpiece material by pressing the

WMAT soft key.

In the NC program, let the TOOL CALL block automatically

calculate spindle speed and feed rate via soft key

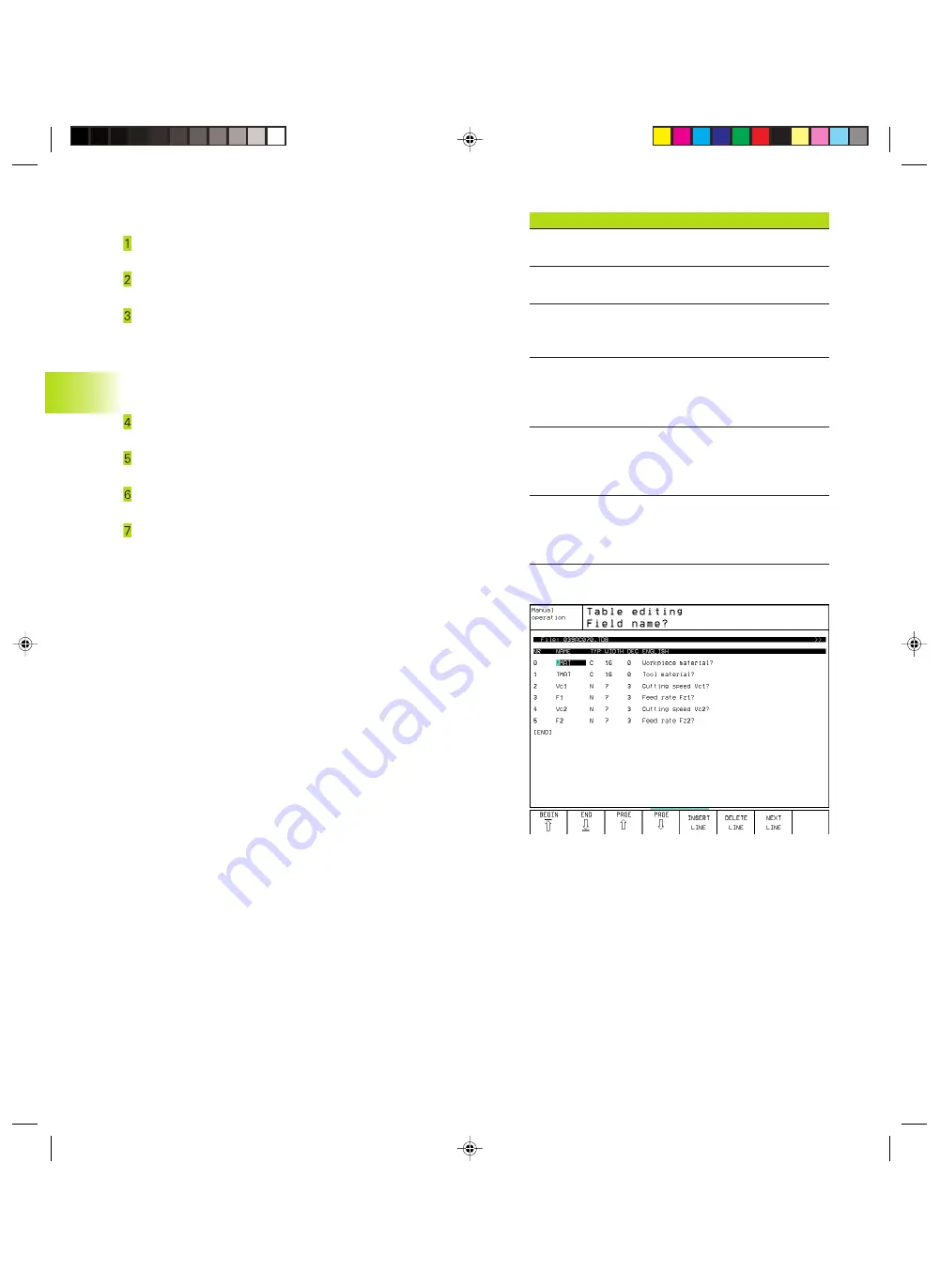

Changing the table structure

Cutting data tables constitute so-called „freely-definable tables“ for

the TNC. You can change the format of freely definable tables by

using the structure editor.

Calling the structure editor

Press the EDIT FORMAT soft key (2nd soft-key level). The TNC

opens the editing window (see figure at right), in which the table

structure is shown ”rotated by 90°.” In other words, a line in the

editing window defines a column in the associated table. The

meanings of the structure commands (header entries) are shown in

the table at right.

Exiting the structure editor.

Press the END key. The TNC changes data that was already in the

table into the new format. Elements that the TNC could not convert

into the new structure are indicated with a hash mark # (e.g., if you

have narrowed the column width).

Fkap5.pm6

30.06.2006, 07:03

88

www.EngineeringBooksPdf.com

Summary of Contents for TNC 426 B

Page 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Page 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Page 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Page 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Page 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Page 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Page 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Page 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Page 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Page 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Page 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Page 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Page 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Page 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Page 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Page 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...