7 Programming: Miscellaneous functions

146

Automatic compensation of machine geometry

when working with tilted axes: M114

Standard behavior

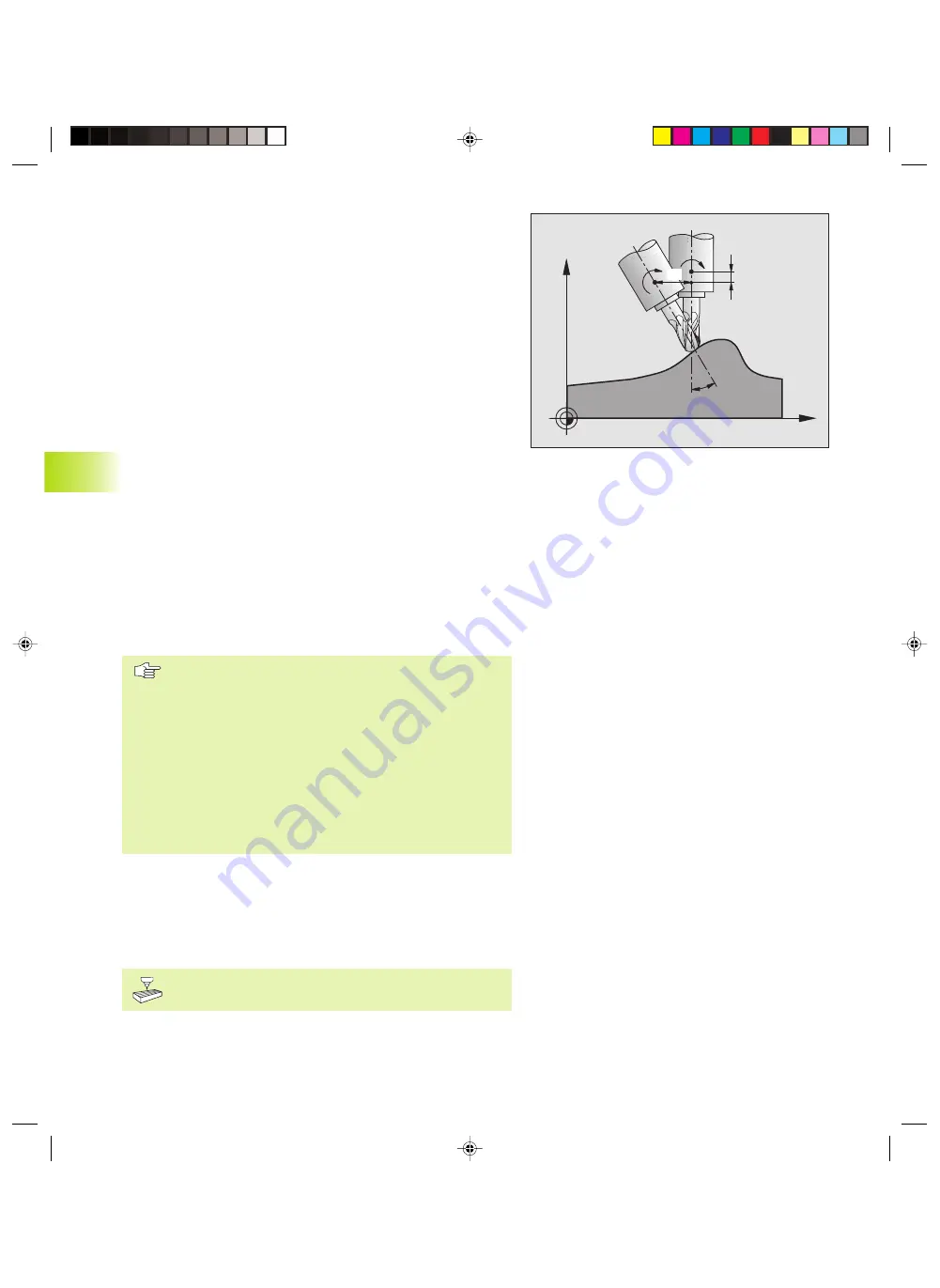

The TNC moves the tool to the positions given in the part program.

If the position of a tilted axis changes in the program, the resulting

offset in the linear axes must be calculated by a postprocessor (see

figure at top right) and traversed in a positioning block. As the

machine geometry is also relevant, the NC program must be

calculated separately for each machine tool.

Behavior with M114

If the position of a controlled tilted axis changes in the program, the

TNC automatically compensates the tool offset by a 3-D length

compensation. As the geometry of the individual machine tools is

set in machine parameters, the TNC also compensates machine-

specific offsets automatically. Programs only need to be calculated

by the postprocessor once, even if they are being run on different

machines with TNC control.

If your machine tool does not have controlled tilted axes (head tilted

manually or positioned by the PLC), you can enter the current valid

swivel head position after M114 (e.g. M114 B+45, Q parameters

permitted).

The radius compensation must be calculated by a CAD system or

by a postprocessor. A programmed radius compensation RL/RR will

result in an error message.

If the tool length compensation is calculated by the TNC, the

programmed feed rate refers to the point of the tool. Otherwise it

refers to the tool datum.

If you machine tool is equipped with a swivel head that

can be tilted under program control, you can interrupt

program run and change the position of the tilted axis,

for example with the handwheel.

With the RESTORE POS. AT N function, you can then

resume program run at the block at which the part

program was interrupted. If M114 is active, the TNC

automatically calculates the new position of the tilted

axis.

If you wish to use the handwheel to change the position

of the tilted axis during program run, use M118 in

conjunction with M128.

Effect

M114 becomes effective at the start of block, M115 at the end of

block. M114 is not effective when tool radius compensation is

active.

To cancel M114, enter M115. At the end of program, M114 is

automatically canceled.

The machine geometry must be entered in machine

parameters 7510 ff. by the machine tool builder.

7.5 Miscellaneous F

unctions f

o

r

Rotary A

x

e

s

X

Z

dB

dz

dx

B

B

Hkap7.pm6

30.06.2006, 07:03

146

www.EngineeringBooksPdf.com

Summary of Contents for TNC 426 B

Page 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Page 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Page 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Page 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Page 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Page 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Page 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Page 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Page 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Page 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Page 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Page 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Page 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Page 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Page 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Page 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...