A. Flap Handles:

Normal positioning of the flaps is accomplished by a FLAP handle located

on the right side of the cockpit center pedestal. It has four detents that set

the flaps to each of its positions: UP (0°), 10°, Takeoff / Approach (T/O /

APPR [20°]) and DOWN (39°). The handle moves vertically into each

detent. At each detent, operating limit switches control electrical power to

the flap circuitry.

An EMER FLAP handle on the copilot’s side console mechanically controls

the flap selector valve if the normal flap control system malfunctions. The

handle moves vertically to select one of three detents: FLAPS UP,

NEUTRAL (no movement) or FLAPS DOWN. Before using the EMER

FLAP handle, however, the EMERG FLAP switch (just aft of the EMER

FLAP handle) must be in the EMERG position in order to bypass the

normal FLAP handle switches and flap follow-up switches.

If both the Combined and Utility hydraulic systems are not available, the

Auxiliary hydraulic system can be used to position the flaps using the AUX

pump. In this scenario, the normal FLAP handle would still be used.

During normal FLAP handle operation, both the FLAP CONT and MANUAL

FLAP CONT circuit breakers must be set. During EMER FLAP handle

operation, only the MANUAL FLAP CONT circuit breaker must be set.

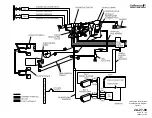

B. Flap Shutoff Valve:

A normally closed (spring-loaded) shutoff valve controls hydraulic fluid flow

to the flap selector valve. Electrically controlled by the flap control relay and

the follow-up switches, the valve is energized open to allow fluid flow to the

selector valve.

If an asymmetrical flap condition occurs, the flap asymmetry switches open

the flap control relay to de-energize the flap shutoff valve and stop

hydraulic pressure flow to the flap selector valve. Flap movement ceases at

this point.

C. Flap Selector Valve:

The solenoid-operated flap selector valve directs hydraulic pressure flow to

the hydraulic motor. When electrically actuated by the FLAP handle, one of

the valve’s two solenoids energizes to supply hydraulic pressure to the

hydraulic motor to drive it in the required direction to extend or retract the

flaps. When the flaps reach the commanded position, flap follow-up

switches de-energize the flap selector valve through the control relay.

Hydraulic pressure flow to motor is shut off and the motor stops.

Two flow regulators limit hydraulic fluid flow to the hydraulic motor to 2.6

Gallons Per Minute (GPM) and from the motor to return at 2.9 GPM.

D. Hydraulic Motor and Central Gearbox:

A fixed-displacement hydraulic motor powered by the Combined, Utility or

Auxiliary hydraulic systems provides power to the flap system central

gearbox. The gearbox employs 8.22:1 reduction gears to provide a 730

RPM output that drives the flap actuators.

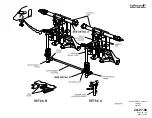

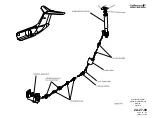

The gearbox has three output shafts that drive the left and right flap

actuators and the horizontal stabilizer actuator. An additional output shaft

drives the flap follow-up switch assembly and flap position transmitter.

Multi-section torque shafts transmit rotational force from the gearbox to the

OPERATING MANUAL

PRODUCTION AIRCRAFT SYSTEMS

2A-27-00

Page 56

January 31/02

Revision 6

Summary of Contents for IV

Page 17: ...Pitch Trim Controls Figure 5 OPERATING MANUAL 2A 27 00 Page 21 22 January 31 02 ...

Page 32: ...Rudder Pedals Forward Linkage Figure 13 OPERATING MANUAL 2A 27 00 Page 39 40 January 31 02 ...

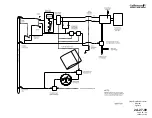

Page 50: ...Flaps Simplified Block Diagram Figure 18 OPERATING MANUAL 2A 27 00 Page 61 62 January 31 02 ...