100

From 2/4

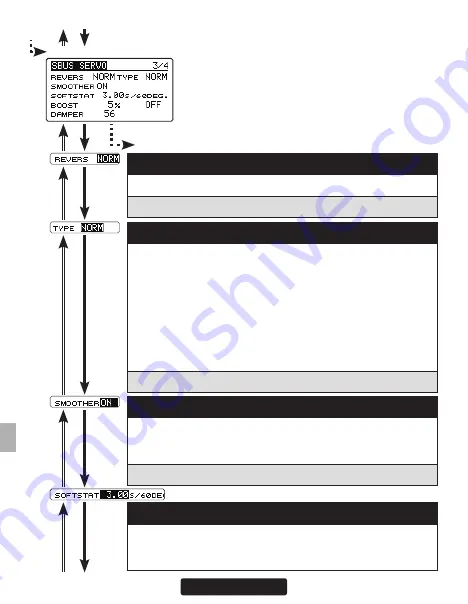

SBUS SERVO screen 3/4

Go to 4/4 from any cursor position

(7) REVERS

The direction in which the servo rotates can be changed.

Setting: NORM / REV

(9) SMOOTHER

This function changes smoothness of the servo operation relative

to operation signal changes. Normally use at Smooth setting. Es-

pecially, select the "OFF" mode when quick operation is necessary.

Setting: ON / OFF Initial setting: ON

(10) SOFTSTART

Restricts operation in the specified direction the instant the power is

turned on. By making this setting, only the first operation when the

power is turned on slowly moves the servo to the specified position.

(8) TYPE

When "Retractable" is selected and the servo has been continu-

ously stopped for 30 seconds, the dead band expands and unnec-

essary hold current due to external force is eliminated. When a new

control signal enters, normal operation is resumed. When using the

servo as a landing gear servo, select "Retractable". Also adjust the

servo travel to match the landing gear movement range. When the

servo type is OLP mode, the torque and time for OLP can be set on

SBUS SERVO screen 4/4. When the load is greater than this set-

ting torque and continues over this setting time, OLP works.

Setting: NORM / OLP / RETR

Summary of Contents for CGY755

Page 112: ......