Operating manual (MC).

CNC 8060

CNC 8065

3.

WORKING

WITH OPERATIONS OR

CYCLES

Ra

ndom multipl

e

ma

ch

ini

ng.

·158·

(R

EF

: 1709)

3.27

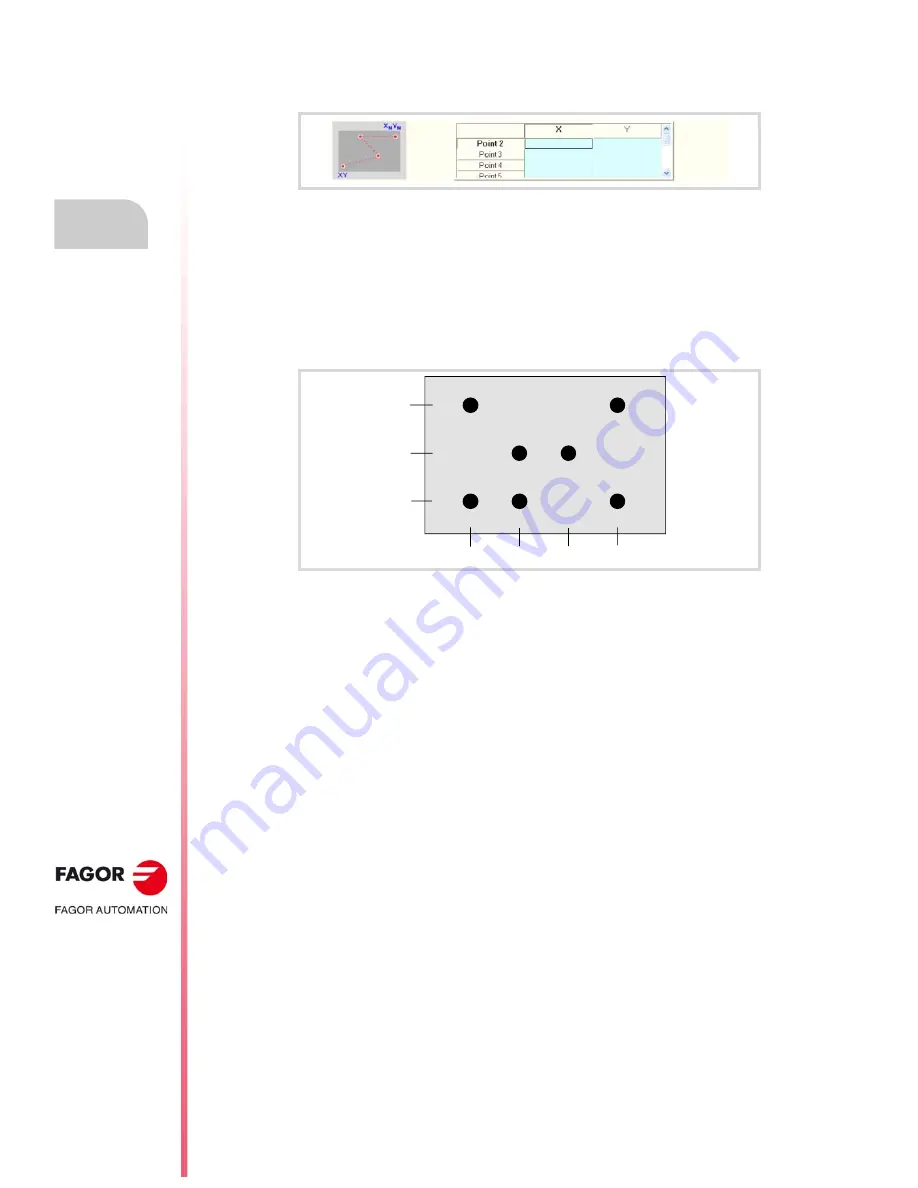

Random multiple machining.

The starting point is the cycle defining point.

The rest of the points (P2) to (P12) must be defined in the area for multiple machining.

When not using all the points, define the first unused point with the same coordinates as those

of the last point of the profile.

Programming example:

The canned cycle defined at point X25, Y25 is to be repeated at the rest of the points.

The canned cycle is defined at point (P1) X25, Y25

The rest of the points (P2) to (P7) must be defined in the area for multiple machining.

Since there are only 7 points, you must define (P8) = (P7).

(P2)

X 50

Y 25

(P3)

X 100

Y 25

(P4)

X 75

Y 50

(P5)

X 50

Y 50

(P6)

X 25

Y 75

(P7)

X 100

Y 75

(P8)

X 100

Y 75

( P 1 )

( P 2 )

( P 3 )

( P 4 )

( P 5 )

( P 6 )

( P 7 )

2 5

5 0

7 5

1 0 0

7 5

5 0

2 5

Summary of Contents for CNC 8060

Page 1: ...Ref 1709 8060 8065 CNC Operating manual MC...

Page 8: ...BLANK PAGE 8...

Page 14: ...BLANK PAGE 14...

Page 16: ...BLANK PAGE 16...

Page 18: ...BLANK PAGE 18...

Page 22: ...BLANK PAGE 22...

Page 24: ...BLANK PAGE 24...

Page 26: ...BLANK PAGE 26...

Page 169: ...Operating manual MC CNC 8060 CNC 8065 169 User notes REF 1709...

Page 170: ...Operating manual MC CNC 8060 CNC 8065 170 User notes REF 1709...

Page 171: ...Operating manual MC CNC 8060 CNC 8065 171 User notes REF 1709...