6

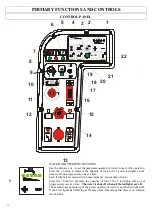

RESPONSIBILITIES OF THE OPERATOR

-

The operator is responsible for the day-to-day servicing of the machine

-

The operator must care for the machine and keep it in good operating condition

-

The operator must inform his or her superior or the technical department when scheduled maintenance is requested in

the case of damage or breakage.

-

The operator must not carry people, animals or objects on the machine.

-

When moving the machine, observe the safety measures for circulation.

-

The machine cannot be used for toxic-harmful materials.

-

Never let people get close to the machine’s sphere of action.

-

Never leave the scrubber-dryer with the key and the emergency switch inserted.

-

Engage the hand brake

-

If the machine malfunctions, have a look at the procedures shown in the various chapters.

-

Never collect pieces of string, wire or anything else that could damage the brushes by winding around them.

-

Never suck up pieces of wood, plastic waste etc. as they may clog the vacuum pipe.

-

Never remove or alter the plates on the machine

DISPOSAL

SPENT OILS

Spent oils must not be thrown away into the environment under any circumstances.

They must be given to authorized Collectors in compliance with the regulations currently in force.

Temporary storage must be inside watertight containers with sealed lid to avoid contact with the environment and with

rainwater.

The filters must also be given to authorized collectors and temporarily kept like the oils.

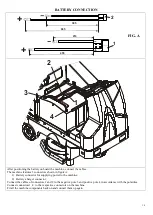

DEAD LEAD BATTERIES

Dead batteries must be considered harmful toxic waste, they must be given only to Collectors with specific authorization

(to be checked at the time of consignment).

SCRAPPING OF THE MACHINE

When the machine is to be scrapped, it is necessary to dispose of the materials the machine consists of, properly.

It is compulsory to give the machine to authorized collectors who will see to the proper disposal of: batteries, oils, filters,

plastics, metals, electric engines, electric cards etc. in accordance with the regulations currently in force.

DISPOSAL OF THE RECOVERY SOLUTION TANK

Prior to be moved on specific purification plants, the recovery tank solution is to be disposed of in the appropriate sites.

TRANSPORT – HANDLING

TRANSPORT

The machine must be fixed to a pallet to make it easier to transport and more secure.

At the reception of the machine, check that the packaging is in good condition –in case of damage, report to the

forwarder.

PAY PARTICULAR ATTENTION WHILE TRANSPORTING THE MACHINE AT TEMPERATURES BELOW 0°C

TO PREVENT THE WATER INSIDE THE TANKS AND THE PIPES FROM BECOMING FROZEN.

DRAIN THE TANKS, REMOVE THE SCREEN OF THE CLEAN SOLUTION FILTER AND LET THE WATER

FLOW AWAY COMPLETELY OUT OF THE PIPES.

TRANSPORT- HANDLING

When the machine is moved from one place to another you are advised to:

- not load it on the vehicle with a forklift truck in order not to damage it

- lock the machine in place with the parking brake

- fix it well to the vehicle using belts, ropes and chains.

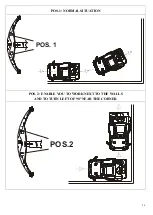

TRANSPORTING THE MACHINE BY MANUAL PUSHING

In case of transport by means of manual pushing –for machines featuring electronic traction only - the machine must be

pushed on at walking pace. Do not tow it with fork lifts.