Service Manual

Adjustments

4.1 ADJUSTING THE PRINTER MECHANISM

This section describes the adjustments you may need to make to the printer mechanism.

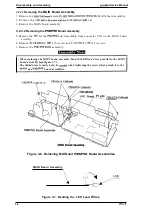

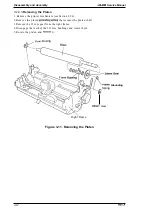

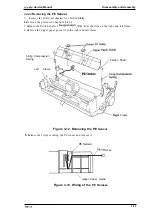

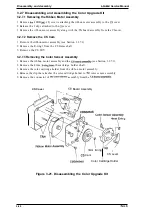

4.1.1 Platen Gap Adjustment

If

you have rotated or reassembled the CR guide shaft assembly or the parallelism adjustment

bushing, or if printing is abnormal, you must adjust the platen and the

1.

2.

3.

4.

5.

6.

7.

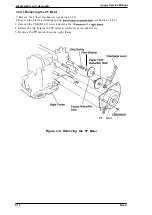

Set the release lever to the friction position.

Remove the upper housing assembly (see Section 3.2.1).

Set the gap adjustment lever to O.

Remove the

Remove the ribbon mask with a pair of tweezers.

Install the

Adjust the platen gap using the flowchart below. The correct platen gap 0.455 mm

0.015 mm. When measuring the gap, take care to let the gauge fall between the platen and the

by gravity only. To

the platen gap, turn the parallelism adjustment bushing

toward the platen using a screwdriver. To reduce the platen gap, turn the parallelism

adjustment bushing away from the platen.

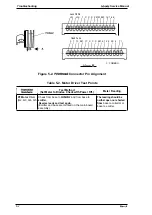

S T A R T

Adjust the platen

YES

Is

the

platen

NO

Adjust the platen

gap correct on the

gap on the right

right

side?

side.

YES

Is the

platen

NO

gap correct on the

left side?

YES

Figure 4-1. Flowchart for Platen Gap Adjustment

4-1

Summary of Contents for LQ-300 - Impact Printer

Page 1: ...EPSON TERMINAL PRINTER LQ 300 SERVICE MANUAL EPSON ...

Page 5: ...REVISION SHEET Revision Issue Date Revision Page Rev A September 28 1994 1st issue f v 1 ...

Page 34: ...c f ...

Page 101: ...Maintenance LQ 300 Service Manual Figure 6 1 LQ 300 Lubrication Points 6 2 Rev A ...

Page 110: ... Figure A 6 C130 PSB PSE Component Layout ...

Page 112: ...Appendix LC MMS vbeMantd Q ix iyii t v Figure A 8 LQ 300 Exploded Diagram 2 A 12 Rev A ...

Page 119: ... f ...