29

Scout 320 REV 3:2018

5.2 Magazine adjustment

Follow the procedure below anytime the bar diameter requires changing.

Caution when adjusting the magazine be sure the lathe and bar feeder

is in emergency stop

Caution, adjusting the magazine can produce pinch points between

magazine and material

Caution when lifting material into the magazine, 2 or more people or a

lifting device may be required to load material

1. Place the lathe and bar feeder into emergency stop prior to adjusting magazine

2. Remove any material from the magazine

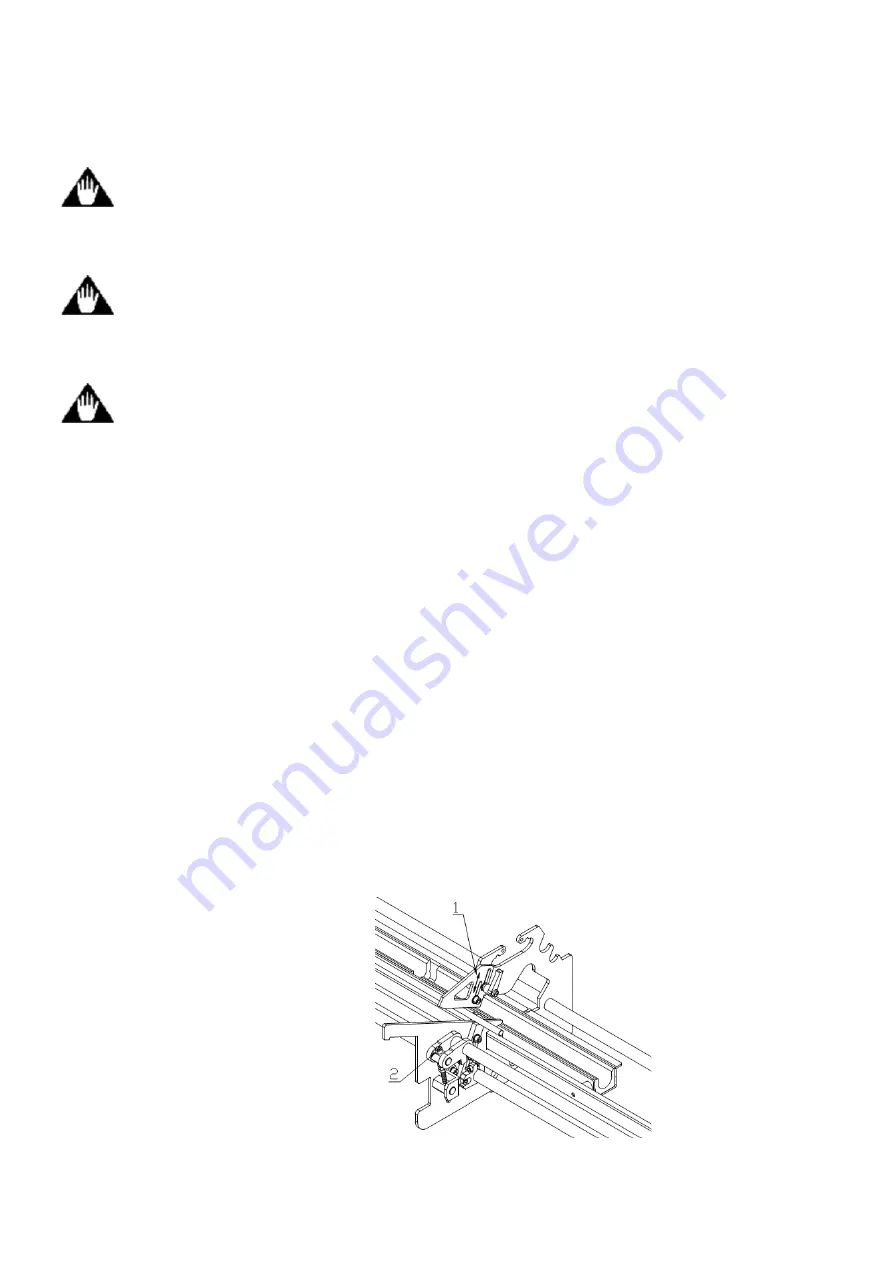

3. Loosen the locking lever for the support plate (1) and lift the plate to the highest position

4. Place one bar to be loaded on the magazine

5. Rotate the screw (2) to adjust the bar stop so that only the first bar on the magazine is

lifted into the guide channel. While you rotate the screw you will see the lift plate move in

the direction the screw is rotated

6. Loosen the lever (1) and slide the support plate down to 1mm over the bar to be

machined.

7. Tighten the lever (1)

8. Load the desired material requirement

9. Close the bar feeder hood.

10. Reset emergency stops on the lathe and bar feeder

11. Repeat above steps when changing bar diameters

1. Lever

2. Adjustment screw