63

9. Ethernet/IP

Dual port ethernet option board installation manual

MN032004EN October 2017 www.eaton.com

9.3.1.1 ODVA Output instances

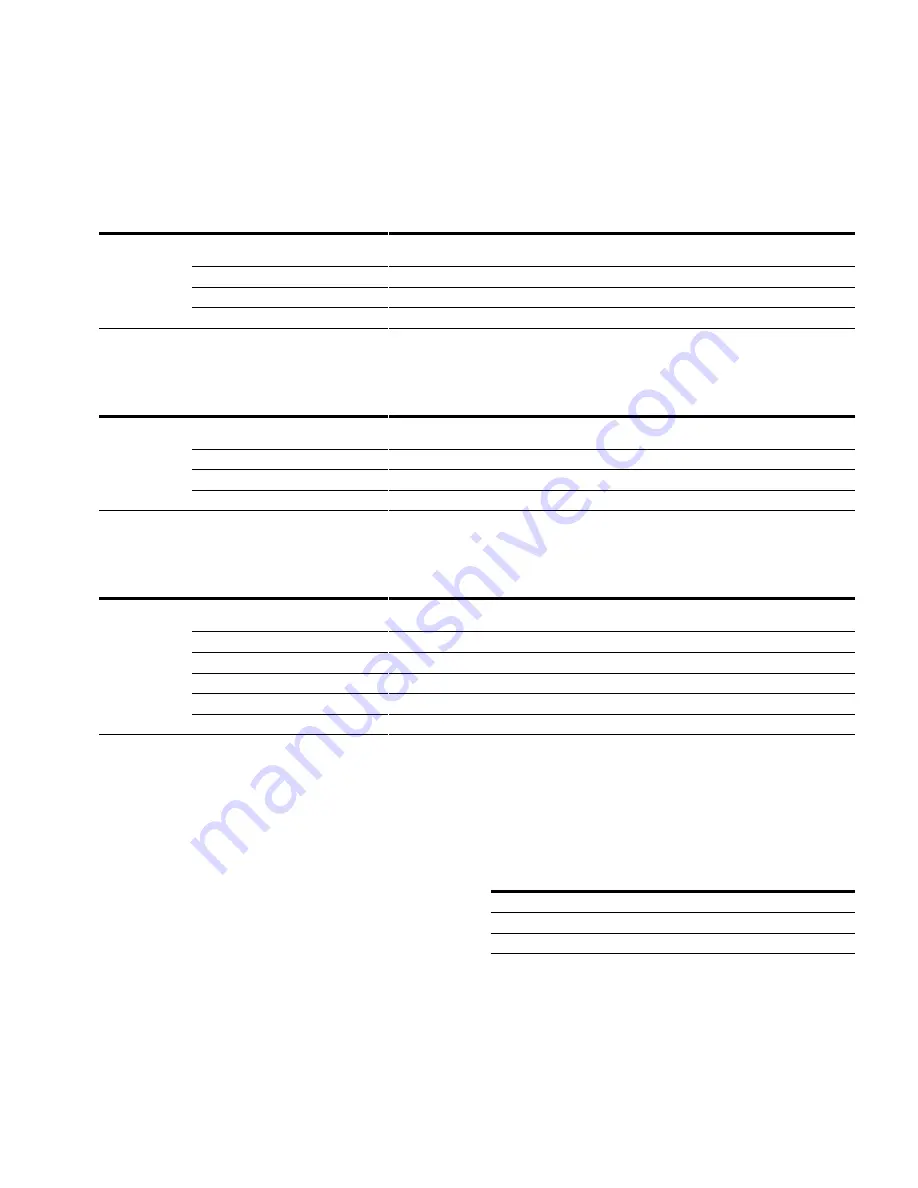

9.3.1.1.1. Assembly instance 20 – basic speed control output

Table 136.

Instance

Octet

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

20 (length 4)

0

Fault

Reset

Run

Fwd

1

2

Speed Reference (Low Octet)

3

Speed Reference (High Octet)

9.3.1.1.2. Assembly instance 21 – extended speed control output

Table 137.

Instance

Octet

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

21 (length 4)

0

NetRef

NetCtrl

Fault

Reset

Run

Rev

Run

Fwd

1

2

Speed Reference (Low Octet)

3

Speed Reference (High Octet)

9.3.1.1.3. Assembly instance 23 – extended speed and torque control output

Table 138.

Instance

Octet

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

23 (length 6)

0

NetRef

NetCtrl

Fault

Reset

Run

Rev

Run

Fwd

1

2

Speed Reference (Low Octet)

3

Speed Reference (High Octet)

4

Torque Reference (Low Octet)

5

Torque Reference (High Octet)

9.3.1.1.4. Assembly instance 25 – extended process control output

The extended process control assembly can be used to

send process reference value directly to the application.

The Process Reference value destination can be selected

with the Drive Mode byte according to the table below.

This should be configured in the application as the receiving

input. To the other direction (input assembly instance 75),

the ProcessDataOut1 is always mapped to the Process

Actual. Note that the process reference value is sent to the

drive only when NetProc bit is set.

The Eaton drives do not support the actual “Process

Control”-mode. Therefore the Drive Mode cannot be set

to the Process Control by using the AC/DC Drive Object

attribute, and the Drive Mode parameter in this assembly

is only used to select the process reference. With these

mappings, the Process Reference and Process Actual can

be used with an application that supports the PID control.

Table 139. Drive mode selection in process control

Drive Mode

Process reference mapping

0

ProcessDataIn1

4

ProcessDataIn2

Other

Not valid