SmartVue Operator’s Manual

10-0004-R13

93

5.

Press

OK.

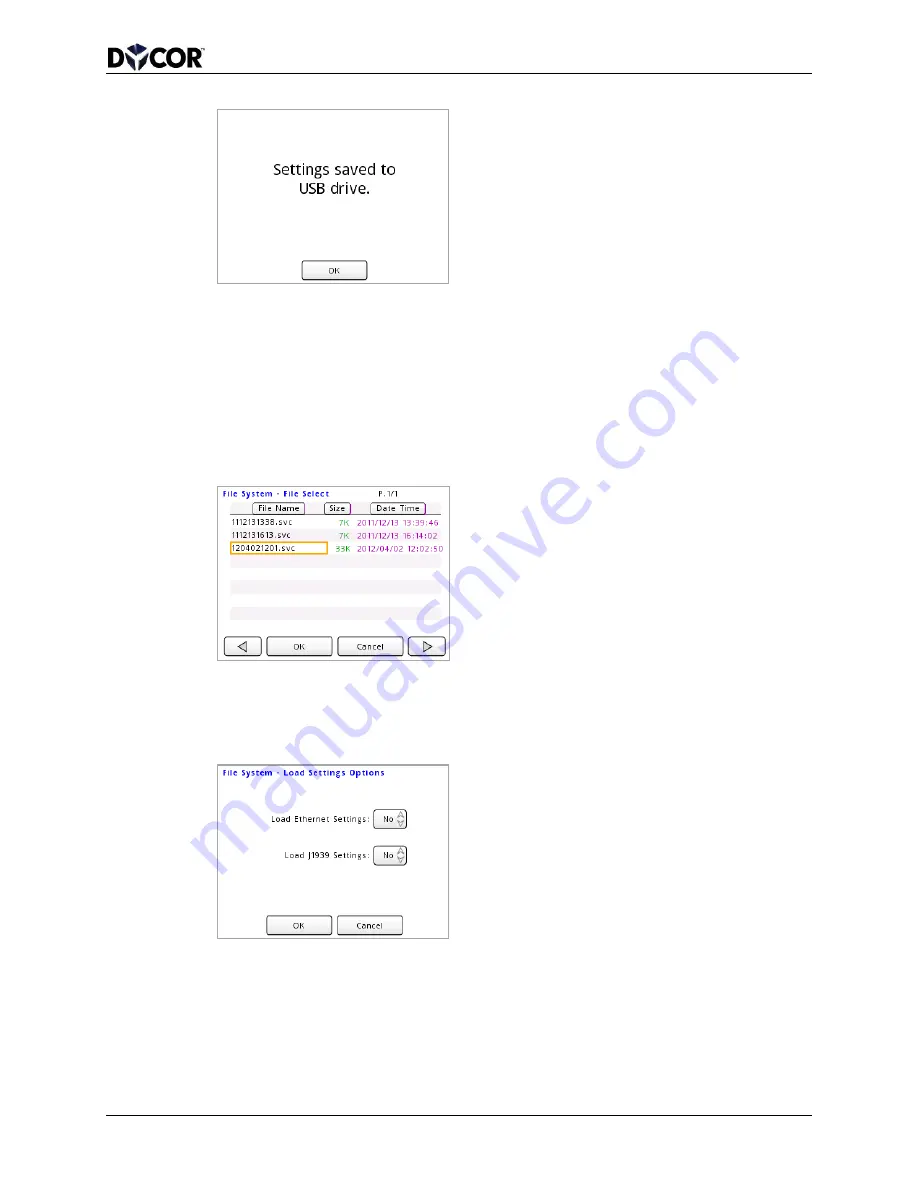

To load a SmartVue configuration file from a USB flash drive

1.

Insert a USB flash drive into the USB port.

2.

Select

Main Menu > File System > Load Settings. This will display a File

Select screen listing all .svc files on the flash drive along with the file size and a

Date/Timestamp. Press a file name to select it.

3.

Press

OK. When loading a configuration file, you have the option of preserving

the current Ethernet and/or J1939 communications settings without overwriting

them with the settings in the file. Specify

Yes if you wish to load the settings

stored in the file you selected.

4.

Press

OK. A warning message is displayed to remind you that the newly loaded

processes and outputs will be disabled until they are manually run.