OP000596

Safety

1-42

Precautions with High-pressure Lines,

Tubes and Hoses

When inspecting or replacing high-pressure piping or hoses,

check that the pressure has been released from the circuit.

Failure to release the pressure may lead to serious injury.

Always do the following;

•

Wear protective glasses and leather gloves.

•

Fluid leaks from hydraulic hoses or pressurized

components can be difficult to see but pressurized oil

has enough force to pierce the skin and cause

serious injury. Always use a piece of wood or

cardboard to check for suspected hydraulic leaks.

Never use your hands or expose your fingers.

•

Do not bend high-pressure lines. Do not strike

high-pressure lines. Do not install lines, tubes or

hoses that are bent or damaged.

•

Make sure that all clamps, guards and heat shields

are installed correctly to prevent vibration, rubbing

against other parts, and excessive heat during

operation.

–

If any of the following conditions are found,

replace the part.

–

Damage or leakage from hose end.

–

Wear, damage, cutting of covering, or exposure

of strengthening wire layer.

–

Cover portion is swollen in places.

–

There is twisting or crushing at movable parts of

hose.

–

Foreign material is embedded in the covering.

–

Hose end is deformed.

NOTE:

Refer to “Hose In-service Lifetime Limit

(European Standard ISO 8331 and

EN982 CEN)” on page 4-59, for additional

European regulations.

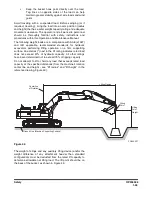

X

X

HDO1045I

Figure 43

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...