OP000599

Inspection, Maintenance and Adjustment

4-14

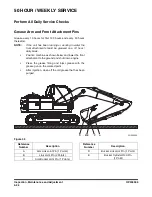

10 HOUR / DAILY SERVICE

Grease Boom, Arm and Front Attachment

Pins (for first 100 hours)

Grease every 10 hours for first 100 hours and every 50 or 250

hours thereafter (See page 4-26).

NOTE:

If the unit has been running or working in water the

front attachment should be greased on a 10 hour /

daily basis.

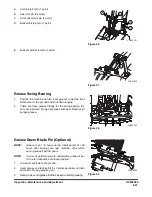

Grease Dozer Blade Pin (Optional) (for first

100 hours)

NOTE:

Grease it per 10 hours during initial period of 100

hours after buying your new machine, after which

period grease it per 50 hours.

NOTE:

In case of performing work underwater, grease it per

10 hours irrespective of elapsed period.

1.

Lower dozer blade to the ground.

2.

Inject grease at total 6 points by 3 points per dozer cylinder

by means of using grease gun.

Neatly remove old grease that has leaked out after greasing.

FG000500

Figure 12

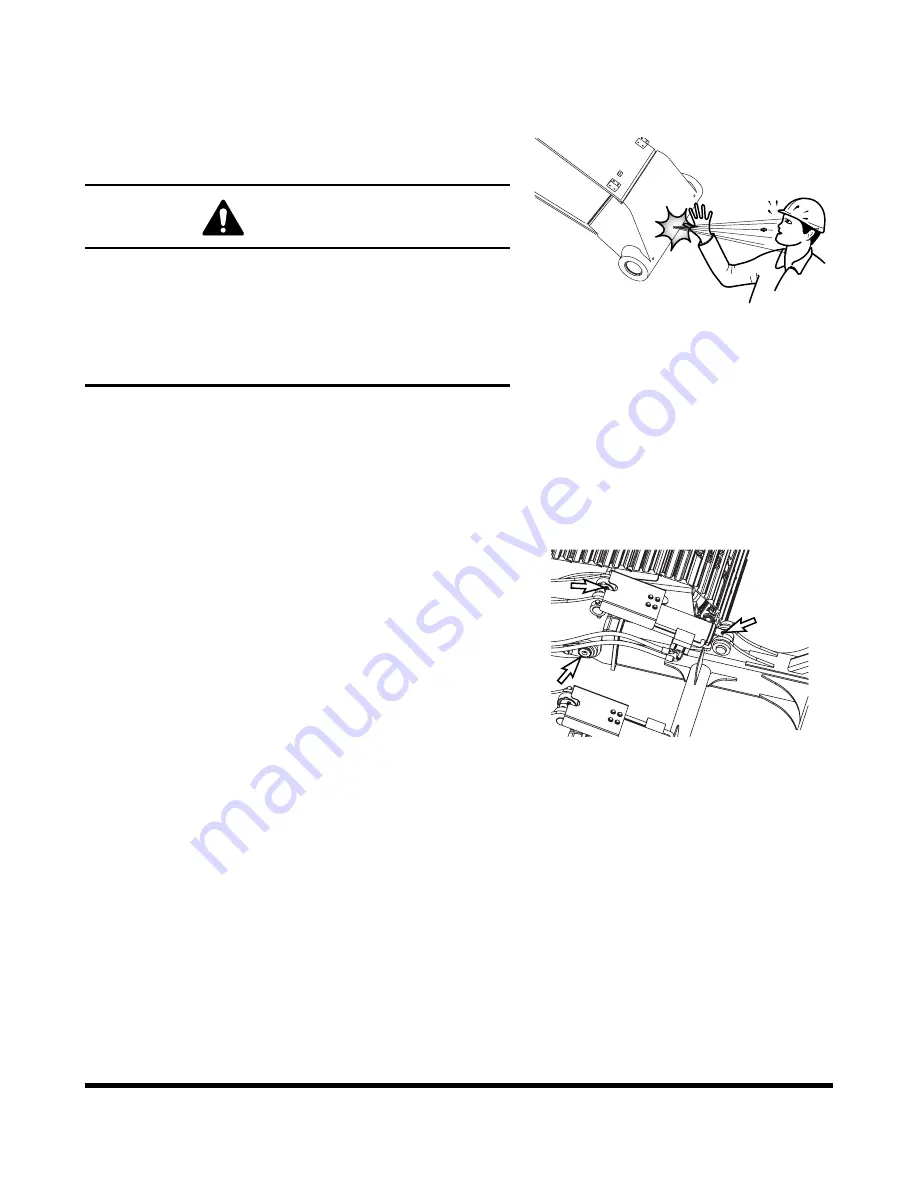

WARNING!

Do not remove the grease fitting until the pressure is

entirely bleed off by loosening grease fitting slowly to avoid

fatal wound.

Let anybody never be in the blowing direction.

Be careful to any kinds of works for nipples and hydraulic

line plugs.

Figure 13

FG009564

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...