OP000599

Inspection, Maintenance and Adjustment

4-56

NOTE:

Based on the type of excavating being completed,

the working conditions (extremely hot or dusty) and

the extra front end attachments being used (hydraulic

breaker, etc.), the hydraulic fluid will need to be

changed more frequently.

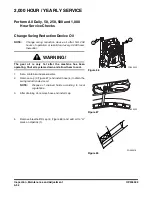

1.

Position the machine on firm, level ground. Swing upper

structure perpendicular (90°) to tracks. Lower boom and

position bucket on ground as shown in Figure 97.

2.

Set safety lever on "LOCK" position.

3.

Shut down engine.

4.

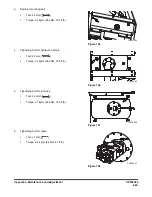

Release pressurized air from hydraulic tank by rotating

breather cap (1, Figure 100).

5.

Drain hydraulic oil from tank into a container capable of

holding 147.8 liters (39 U.S. gal.). After draining tank,

install drain plug.

NOTE:

Used filter and used oil should always be

disposed of according to local regulations.

6.

Carefully remove bolts and cover (2, Figure 100) from top

of hydraulic oil tank. There is a spring (3) under the cover

that will force the cover up.

7.

Remove spring (3, Figure 100) and strainer (5), by pulling

on rod (4).

8.

Clean inside and outside of strainer. Replace strainer if it is

broken.

9.

Position strainer (5, Figure 100) on boss portion of suction

pipe (6).

NOTE:

Measurement "A" is 650 mm (25.59 in).

FG000356

Figure 97

FG009551

Figure 98

IMPORTANT

Be careful of squirting oil when removing drain plug.

HAOC411L

A

Figure 99

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...