OP000599

Inspection, Maintenance and Adjustment

4-20

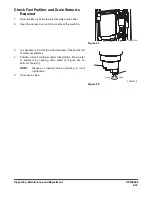

Check Oil Level of Swing Reduction

Device

NOTE:

When checking level using a dipstick always remove

and wipe it clean before making final level check.

1.

Remove dipstick (1, Figure 25) and wipe the oil from the

dipstick with a cloth.

2.

Insert dipstick (1, Figure 25) fully into dipstick tube.

3.

When dipstick is pulled out, oil level must be between

"HIGH" and "LOW" marks on dipstick.

NOTE:

If oil is above "HIGH" mark on dipstick, some

must be drained to proper level.

4.

If the oil does not reach the "L" mark on the dipstick, add oil

through fill port (2, Figure 25).

5.

If the oil level exceeds the "H" mark on the dipstick, open

cap (3, Figure 27) of drain valve and connect hose (4) to

the valve. Drain the excessive oil into a suitable container.

NOTE:

Dispose of drained fluids according to local

regulations.

WARNING!

The gear oil is very hot after the machine has been

operating. Shut all systems down and allow them to cool.

Before fully removing any motor case inspection port plug,

etc., loosen the plug slightly to allow pressurized air to

escape.

Figure 25

2

1

FG009555

L

H

FG000419

Figure 26

Figure 27

3

FG009556

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...