G424F(FE) Service Manual

Chapter 5. Engine Management System (EMS)

153

Other system features include:

Tamper-Resistance

Special tools, equipment, knowledge, and

authorization are required to effect any changes to

the MI-07 system, thereby preventing unauthorized

personnel from making adjustments that will affect

performance or emissions.

Diagnostics

MI-07 is capable of monitoring and diagnosing

problems and faults within the system. These

include all sensor input hardware, control output

hardware, and control functions such as closed-loop

fuel control limits and adaptive learn limits. Upon

detecting a fault condition, the system notifies the

operator by illuminating the MIL and activating the

appropriate fault action. The action required by each

fault shall be programmable by the OEM customer

at the time the engine is calibrated.

Diagnostic information can be communicated

through both the service tool interface and the MIL

lamp. With the MIL lamp, it is possible to generate a

string of flashing codes that correspond to the fault

type. These diagnostics are generated only when

the engine is not running and the operator initiates a

diagnostic request sequence such as repeated

actuations of the pedal within a short period of time

following reset.

Limp Home Mode

The system is capable of "limp-home" mode in the

event of particular faults or failures in the system. In

limp-home mode the engine speed is approximately

1000 rpm at no load. A variety of fault conditions can

initiate limp-home mode. These fault conditions and

resulting actions are determined during calibration

and are OEM customer specific.

Service Tool

A scan tool/monitoring device is available to monitor

system operation and assist in diagnosis of system

faults This device monitors all sensor inputs, control

outputs, and diagnostic functions in sufficient detail

through a single access point to the SECM to allow

a qualified service technician to maintain the system.

This Mototune software (licensed by Mototron

Communication) is secure and requires a crypt-

token USB device to allow access to information.

LPG Fuel System Operation

The principles outlined below describe the operation

of MI-07 on an LPG fuel system.

An LPG fuel system consists of the following

components:

• Fuel filter (supplied by customer)

• Electric fuel lock-off solenoid valve

• Fuel pressure regulator/vaporizer

• Gas/Air mixer

• Miscellaneous customer-supplied hoses and

fittings

Fuel is stored in the customer-supplied LPG tank in

saturated liquid phase and enters the fuel system

from the tank as a liquid and at tank pressure. Fuel

passes through a high-pressure fuel filter and lock-

off solenoid, and is then vaporized and regulated

down to the appropriate pressure to supply the

mixer. The regulator controls the fuel pressure to the

gas/air mixer. The mixer meters fuel delivery based

upon airflow into the engine.

SECM

The Small Engine Control Module (SECM) controls

the LPG lock-off solenoid valve. The lock-off

solenoid is energized when fueling with LPG and the

engine is turning. The lock-off is de-energized when

engine rpm is not detected.

MI-07 LP Fuel Filter

The LP fuel filter of G424F engine is the same as

that of G424FE engine. See, “G424FE EMS

overview”

MI-07 Fuel Lock-Off (Electric)

The LP fuel lock-off of G424F engine is the same as

that of G424FE engine. See, “G424FE EMS

overview”

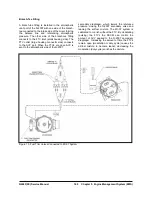

N-2001 Regulator/Converter

After passing through the electric fuel lock-off, liquid

propane enters the N-2001 regulator/converter

(Figure 4). The N-2001 functions as a fuel vaporizer,

converting liquid propane to vapor propane and as a

two-stage negative pressure regulator, supplying the

correct vapor propane fuel pressure to the mixer.

The regulator is normally closed requiring a vacuum

signal (negative pressure) to allow fuel to flow. This

is the second of three safety locks in the MI-07

system. If the engine stops, vacuum signal stops

and fuel flow will automatically stop when both the

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...