G424F(FE) Service Manual

Chapter 4. Engine Electrical System

117

The result of these switches and relays is to permit a

5 amp dash-mounted switch to turn on a 500 to

1000amp motor used to crank an engine. Battery

voltage (power) available during cranking varies

according to the temperature of the batteries. The

following chart is a guide as to what to expect from a

normal system.

TYPICALSYSTEM VOLTAGE DURING

CRANKING AT VARIOUS AMBIENT

TEMPERATURES

Temperature 12V

System

-23 to -7 C (-10 to 20 F)

6 to 8 Volts

-7 to 10 C (20 to 50 F)

7 to 9 Volts

10 to 27 C (50 to 80 F)

8 to 10 Volts

Figure 1

The next chart shows maximum acceptable voltage

loss in the high current battery circuit feeding the

starting motor. These values are maximums for

machines of approximately 2000 SMH and up.

Newer machines would be less than those shown.

MAXIMUM ACCEPTABLE SYSTEM VOLTAGE

DROPS DURING CRANKING

Circuit 12V

System

Battery(-) post to starting motor (-)

terminal

0.7 Volts

Battery (+) post to solenoid (+)

terminal

0.5 Volts

Solenoid Bat terminal to solenoid

Mtr terminal

0.4 Volts

Figure 2

Voltages greater than those shown are most often

caused by loose and/or corroded connections or

defective switch contacts.

Diagnosis Procedure

TOOLS NEEDED

Digital Multimeter or Equivalent

1

DC Clamp-On Ammeter or Equivalent

1

NOTICE

Do not operate the starting motor for more than

30seconds at a time. After 30 seconds, the cranking

must be stopped for two minutes to allow the

starting motor to cool. This will prevent damage to

the starting motor due to excessive heat buildup.

If the starting motor cranks real slow or does not

crank at all, do the following procedure:

1.

Measure battery voltage at the battery posts with

the multimeter while cranking or attempting to

crank the engine. Make sure to measure the

battery posts. Do not measure the cable post

clamps.

2.

Is battery voltage equal to or greater than shown

in Figure 1?

• If the battery voltage is correct, go to Step 3.

• If the battery voltage is too low, Charge or

replace the battery.

NOTE:

Alow battery can be caused by battery

condition or a shorted starting motor.

3.

Measure current draw on the (+) battery cable

between the battery and the starting motor

solenoid with the clamp-on ammeter. The

maximum current draw allowed is 350 Amp. At

temperatures below27°C (80°F), the voltage will

be less and the current draw will be higer. If

current draw is too much, the starting motor has a

problem and must be removed for repair or

replacement.

NOTE:

If voltage at the battery post is within

approximately 2 volts of the lowest value in the

applicable temperature range of Figure1 and if the

large starting motor cables get hot, then the starting

motor has a problem and the Ammeter test is not

needed.

4.

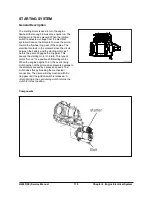

Measure starting motor voltage from test point (4)

to (5) with the multimeter while cranking or

attempting to crank the engine.

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...