G424F(FE) Service Manual

Chapter 5. Engine Management System (EMS)

146

Speed Management

Drive-by-wire refers to the fact that the MI-07 control

system has no throttle cable from the foot pedal to

the throttle body. Instead, the SECM is electronically

connected both to the foot pedal assembly and the

throttle body.

The SECM monitors the foot pedal position and

controls the throttle plate by driving a DC motor

connected to the throttle. The DC motor actuates the

throttle plate to correspond to the foot pedal position

when the operator depresses the pedal. The SECM

will override the pedal command above a maximum

engine speed and below a minimum idle speed.

Figure 19. Foot Pedal

The use of electronic throttle control (ETC) ensures

that the engine receives only the correct amount of

throttle opening for any given situation, greatly

improving idle quality and drivability.

Two throttle position sensors (TPS1 and TPS2),

which are integral to the drive-by-wire (DBW) throttle

assembly, provide feedback for position control by

monitoring the exact position of the throttle valve.

See Figure 20.

SECM self-calibration and “cross checking”

compares both signals and then checks for errors.

Figure 20. Throttle Position Sensor (TPS) on DV-E5

Throttle

NOTE :

The DV-E5 throttle is not a serviceable

assembly. If a TPS sensor fails, the assembly

should be replaced.

The MI-07 system also performs minimum (min) and

maximum (max) speed governing through the

SECM and DBW throttle. For min governing, or idle

speed control, the idle speed is fixed by the SECM.

Unlike a mechanical system, the idle speed is not

adjustable by the end user. The idle speed is

adjusted by the SECM based on engine coolant

temperature. At these low engine speeds, the SECM

uses spark and throttle to maintain a constant speed

regardless of load.

The MI-07 system eliminates the need for air

velocity governors. This substantially increases the

peak torque and power available for a given system

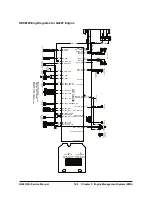

as shown in Figure 21. When the engine speed

reaches the max governing point the speed is

controlled by closing the DBW throttle. Using the

DBW throttle as the primary engine speed control

allows for a smooth transition into and out of the

governor. If excessive over speed is detected, the

engine is shut down.

Figure 21. Peak Torque and Power Available with

MI-07 System

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...