29

EN

5

Maintenance

Danger!

All jobs to be carried out only when

engine switched off and machine at a

standstill. Remove the ignition key!

5.1

Inspection

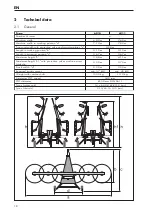

After approx. 5 operating hours, check the Rotary

Tedder thoroughly. All screws, particularly those

fastening the spring-mounted tines, rotary unit arms and

wheels, must be checked and tightened where

necessary.

TTTTTor

or

or

or

orqqqqques:

ues:

ues:

ues:

ues:

z

Spring-mounted tines

= 120 Nm

z

Rotary unit arms, outside = 120 Nm

z

Rotary unit arms, inside

= 155 Nm

z

Wheels

= 20 Nm

5.2

Caring for the cardan shaft

Regular maintenance results in a long service life.

Check proper functioning of the cardan shaft and the

safety parts every time before use. At the end of the

season, clean and lubricate all parts thoroughly.

5.3

Winter storage

Before putting the implement into winter storage, the

following work must be done:

z

Clean the implement thoroughly

z

Check all screwed connections and tighten all

screws

z

Repair or replace all damaged parts

z

Repair any damage to the paintwork

z

Lubricate the implement according to the lubrication

diagram

z

Check tyre pressure

after

after

after

after

after

5 operating hours

5 operating hours

5 operating hours

5 operating hours

5 operating hours

Summary of Contents for CondiMaster 6831

Page 2: ......

Page 4: ...2 EN...

Page 13: ...11 EN 6 Keep clear of the swivel area of the implement...

Page 33: ...31 EN 40 h 8 h 40 h 40 h 8 h 8 h 16 h 40 h Fig 5 1 Fig 5 2...

Page 37: ......