14

EN

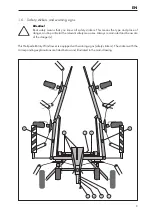

1.8.3 Power take-off operation

1. Do not use cardan shafts other than those specified by the manufacturer!

Make sure that the cardan shaft is always properly installed and secured!

The protecting tube as well as the cardan shaft guard must be installed. All guards must be in

perfect condition! Secure the cardan shaft against rotation by fastening the chains to the tractor

and the implement!

Observe the overlap prescribed for cardan shaft tubes, both in transport and working position!

2. When working with the cardan shaft, no-one is allowed to be in the vicinity of the rotating cardan

shaft!

3. Only attach or remove the cardan shaft when the p.t.o. shaft is disengaged, the engine is off and

the ignition key removed!

Place the detached cardan shaft onto its support!

After the cardan shaft has been detached, slide the protective caps over the p.t.o. stub!

4. The p.t.o. shaft guard must be positioned correctly and in perfect condition! Before engaging the

p.t.o. shaft, make sure the selected speed and direction of rotation of the tractor p.t.o. shaft

corresponds with the permissible speed and direction of rotation of the implement! Before engaging

the p.t.o. shaft, make sure that no-one is in the danger area of the implement!

5. Never engage the p.t.o. shaft when the engine is off!

6. Always disengage the p.t.o. shaft if the angle becomes too wide or if the p.t.o. shaft is not needed!

7.

Attention! Working elements continue to rotate after the p.t.o. shaft is disengaged. Do not approach

the implement for the duration. Make sure the implement has completely stopped rotating before

carrying out any work on it!

8. Before cleaning, lubricating or adjusting the p.t.o.-driven implement or the cardan shaft, disengage

the p.t.o. shaft, stop the engine and remove the ignition key!

9. Repair any damage prior to working with the implement!

1.8.4 Hydraulics

1. Attention! The hydraulic system is under high pressure!

2. Check the hydraulic hoses at regular intervals and renew them when damaged, at the latest,

however, every 6 years! The spare hoses must comply with the technical requirements laid down

by the manufacturer of the implement! Only use genuine parts!

3. Before working on the hydraulics, lower the implements and aggregates. Then release pressure

from the system and stop the engine.

4. When tracing leakages, use suitable tools. Danger of injury!

5. When connecting hydraulic cylinders, make sure the hydraulic hoses are coupled as prescribed!

Pressure should be released from the system both on the tractor and implement side prior to coupling

hydraulic hoses to the tractor hydraulics!

Summary of Contents for CondiMaster 6831

Page 2: ......

Page 4: ...2 EN...

Page 13: ...11 EN 6 Keep clear of the swivel area of the implement...

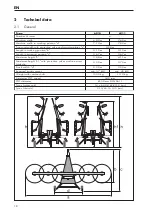

Page 33: ...31 EN 40 h 8 h 40 h 40 h 8 h 8 h 16 h 40 h Fig 5 1 Fig 5 2...

Page 37: ......