28

EN

4

Settings

Danger!

All jobs to be carried out only when

engine switched off and machine at a

standstill. Remove the ignition key!

4.1

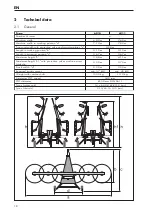

Tine setting

Check the tine setting and readjust if necessary:

z

unscrew hexagonal nut (c) and locknut (d) (fig. 4-1)

z

adjust tines by adjusting the stopper screw (x) so

that the gauge is parallel for (a) and (b) (fig. 4-2).

TTTTType 69

ype 69

ype 69

ype 69

ype 691

11

110:

0:

0:

0:

0: Ang

Ang

Ang

Ang

Angle y = 9

le y = 9

le y = 9

le y = 9

le y = 97°

7°

7°

7°

7°

TTTTType 69

ype 69

ype 69

ype 69

ype 691

11

111:

1:

1:

1:

1: Angle y = 92°

Angle y = 92°

Angle y = 92°

Angle y = 92°

Angle y = 92°

z

Tighten hexagonal nut (c) and locknut (d) again.

The torque for fastening the tines (c) is 120 Nm.

Attention!

The stopper screw (x) must be positioned

at the tine eyelet so that the tine cannot

become misadjusted.

4.2

Wheels

If the wheels have to be changed, the wheel nuts should

only be tightened with 20 Nm to prevent damage to

the plastic rings.

Check tyre pressure regularly:

1.5 bar (16 x 6.50-8 4PR)

2.5 bar (215/65-15)

Fig. 4-1

Fig. 4-2

Summary of Contents for CondiMaster 6831

Page 2: ......

Page 4: ...2 EN...

Page 13: ...11 EN 6 Keep clear of the swivel area of the implement...

Page 33: ...31 EN 40 h 8 h 40 h 40 h 8 h 8 h 16 h 40 h Fig 5 1 Fig 5 2...

Page 37: ......